Platinum RTD sensors are globally recognized as one of the most accurate and stable temperature measurement technologies used in industrial automation today. According to IEC 60751 standards, platinum resistance thermometers such as Pt100 temperature sensors can deliver accuracy levels as tight as ±0.1°C, making them indispensable in industries where even a minor deviation can result in production losses, safety hazards, or regulatory non-compliance. In critical process control environments, accuracy is not optional—it is foundational.

Heatcon Sensors is a specialized temperature sensor manufacturer based in India, delivering customized platinum RTD sensors and allied thermal solutions to industries across India and globally. From petrochemical plants in the Middle East to pharmaceutical facilities in Germany, and from manufacturing hubs in South Korea to energy operations in the United States, Heatcon Sensors ensures reliable, application-specific temperature sensing solutions built for demanding environments.

What are platinum RTD sensors and why are they used in critical process control?

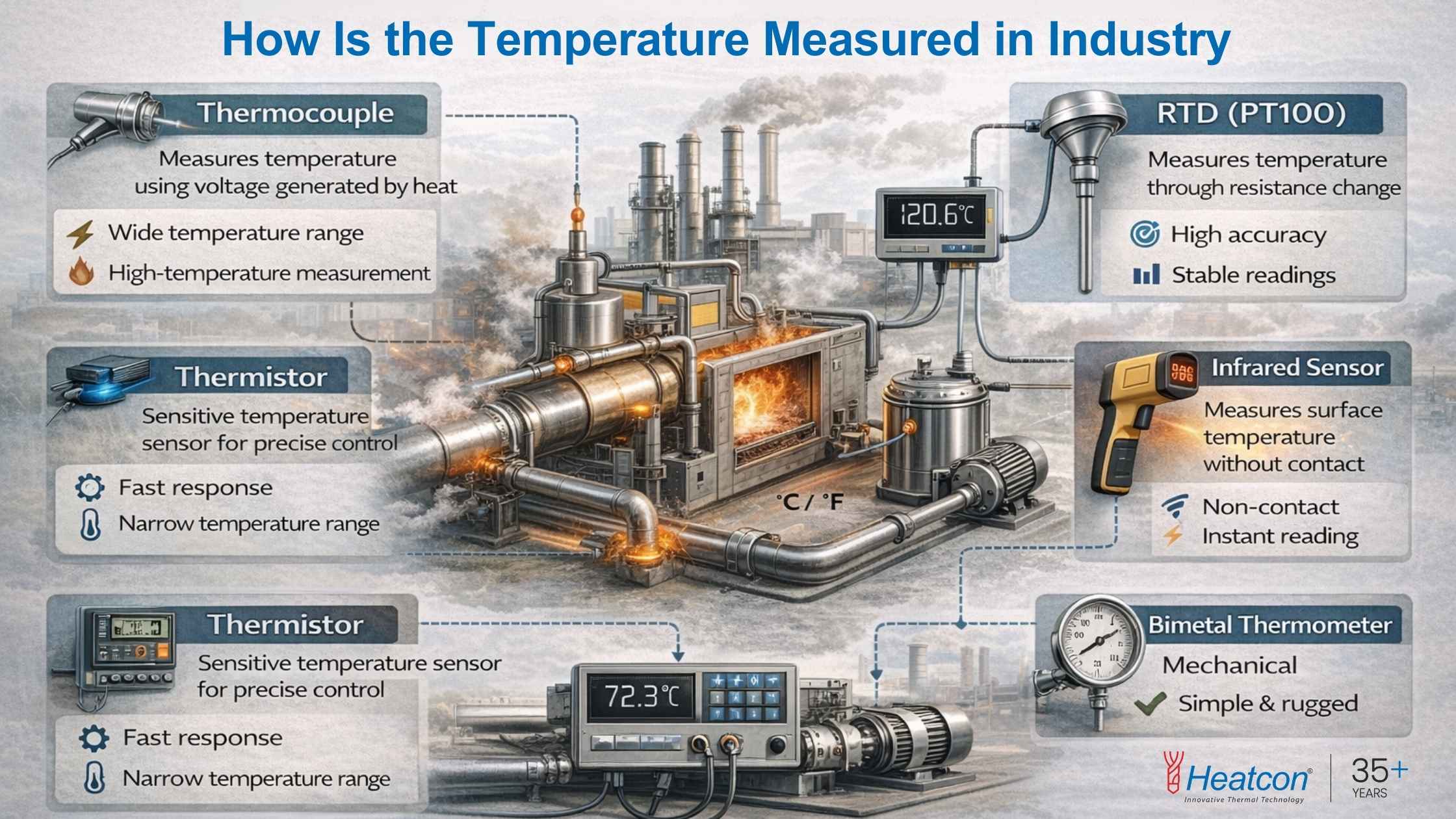

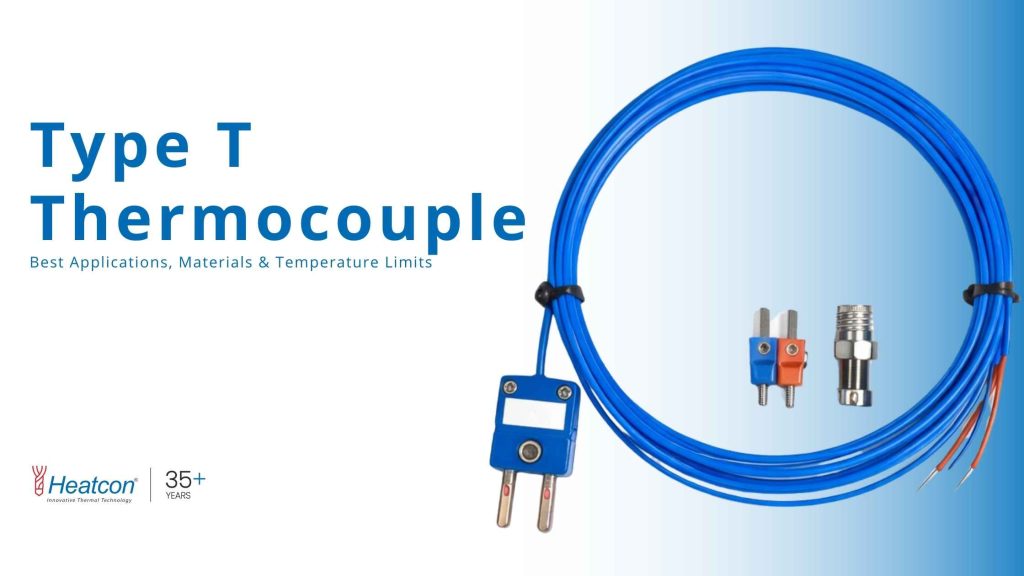

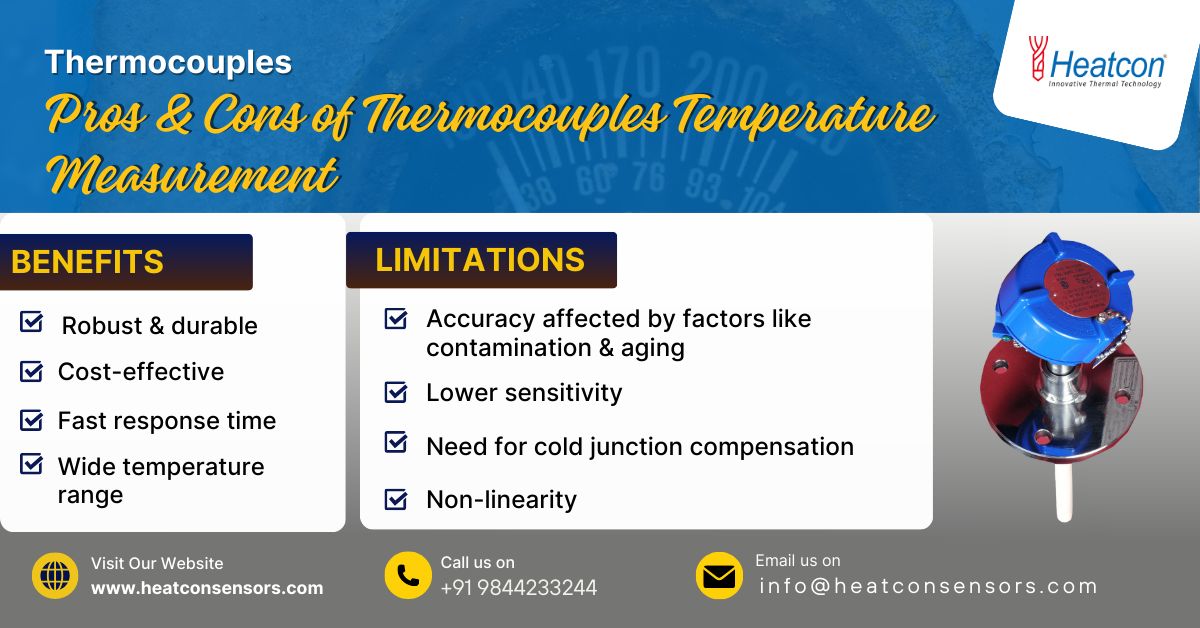

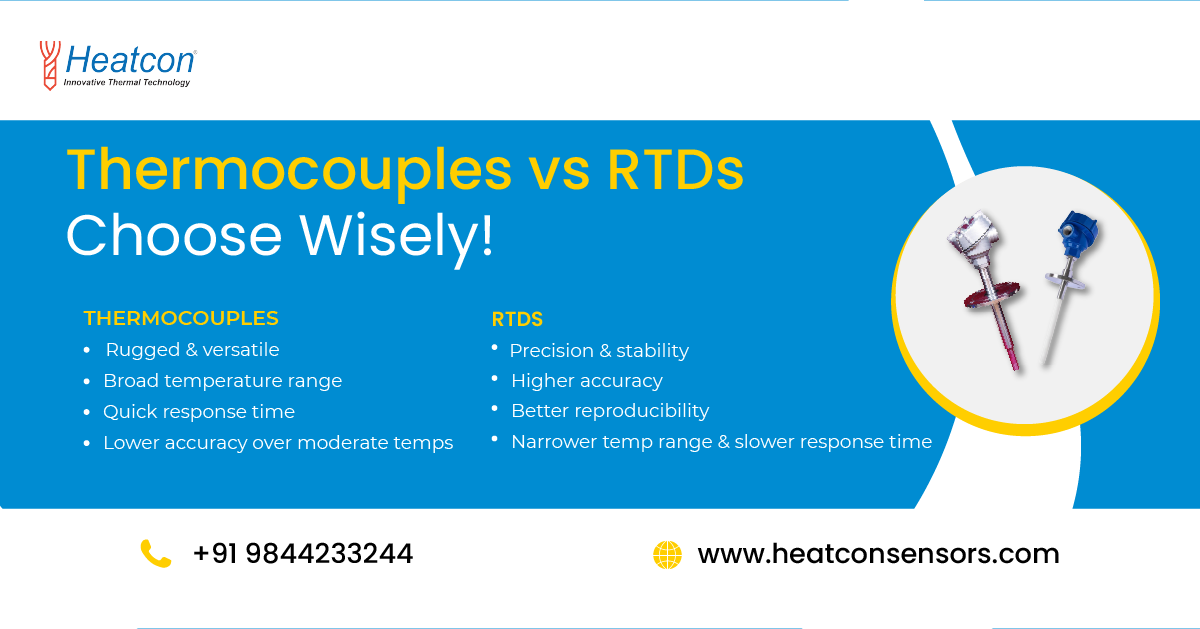

Platinum RTD sensors are temperature sensors that measure heat by correlating the resistance of platinum with temperature. Platinum is chosen because of its stable, repeatable, and predictable resistance characteristics across a wide temperature range. These sensors are widely used in critical process control due to their high accuracy, long-term stability, and resistance to corrosion.

Industries rely on platinum RTD sensors for:

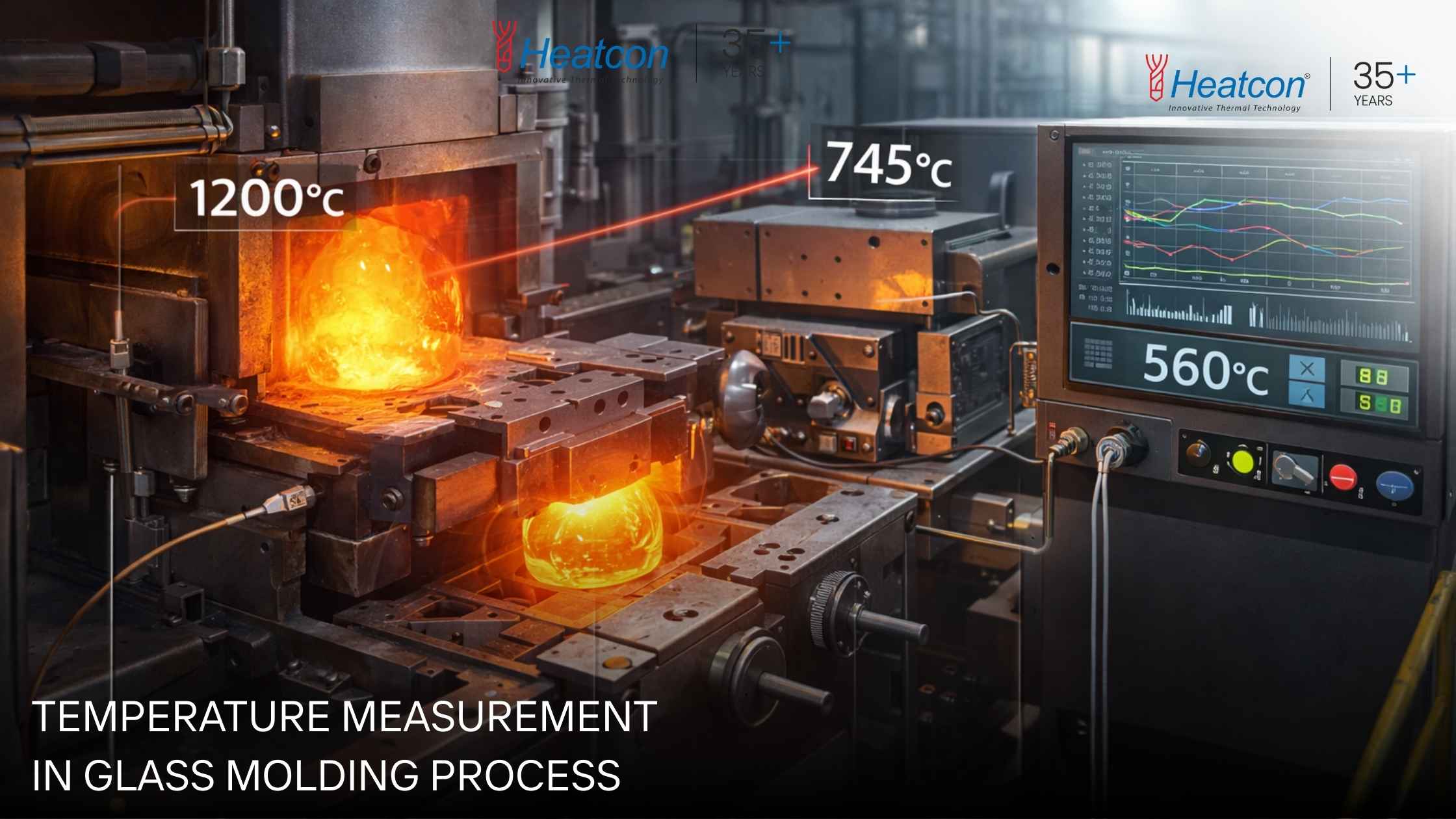

- Precise temperature monitoring in reactors and furnaces

- Calibration reference in laboratories

- Energy and power plant monitoring

- Oil and gas process safety systems

- Pharmaceutical and food-grade processing lines

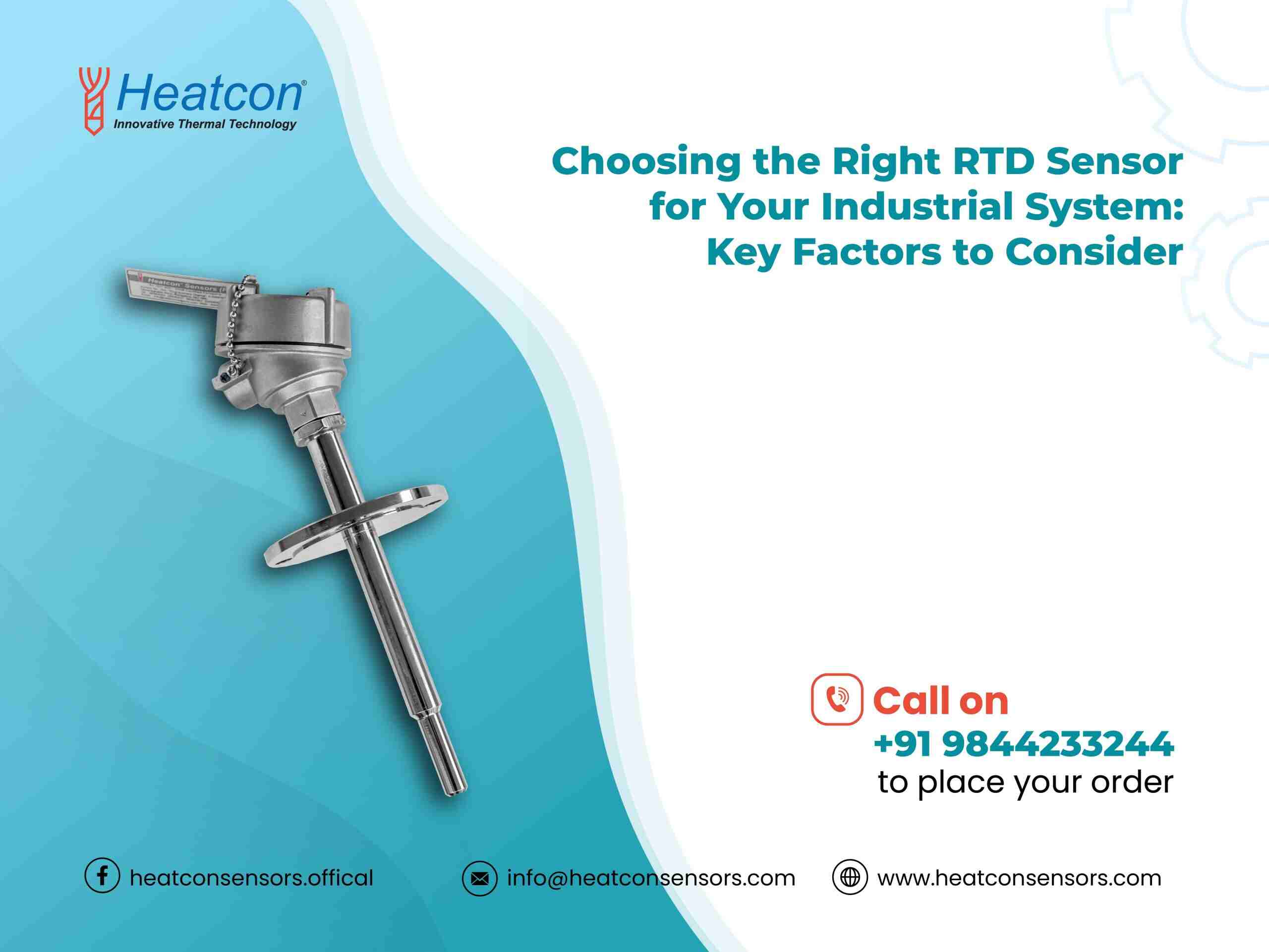

Heatcon Sensors manufactures platinum RTD sensors tailored to specific industrial applications, ensuring correct sheath material, probe diameter, insertion length, and terminal configuration for seamless integration into your systems.

How do Pt100 temperature sensors support industrial accuracy?

Pt100 temperature sensors are a specific type of platinum RTD sensors that have a resistance of 100 ohms at 0°C. Their predictable resistance curve makes them ideal for precision measurement in both low and high temperature applications.

In industries where compliance with ISO, GMP, or ASTM standards is mandatory, Pt100 temperature sensors offer:

- Repeatable and stable output signals

- Excellent linearity over wide temperature ranges

- Compatibility with digital controllers and PLC systems

- Reduced drift over time compared to thermocouples

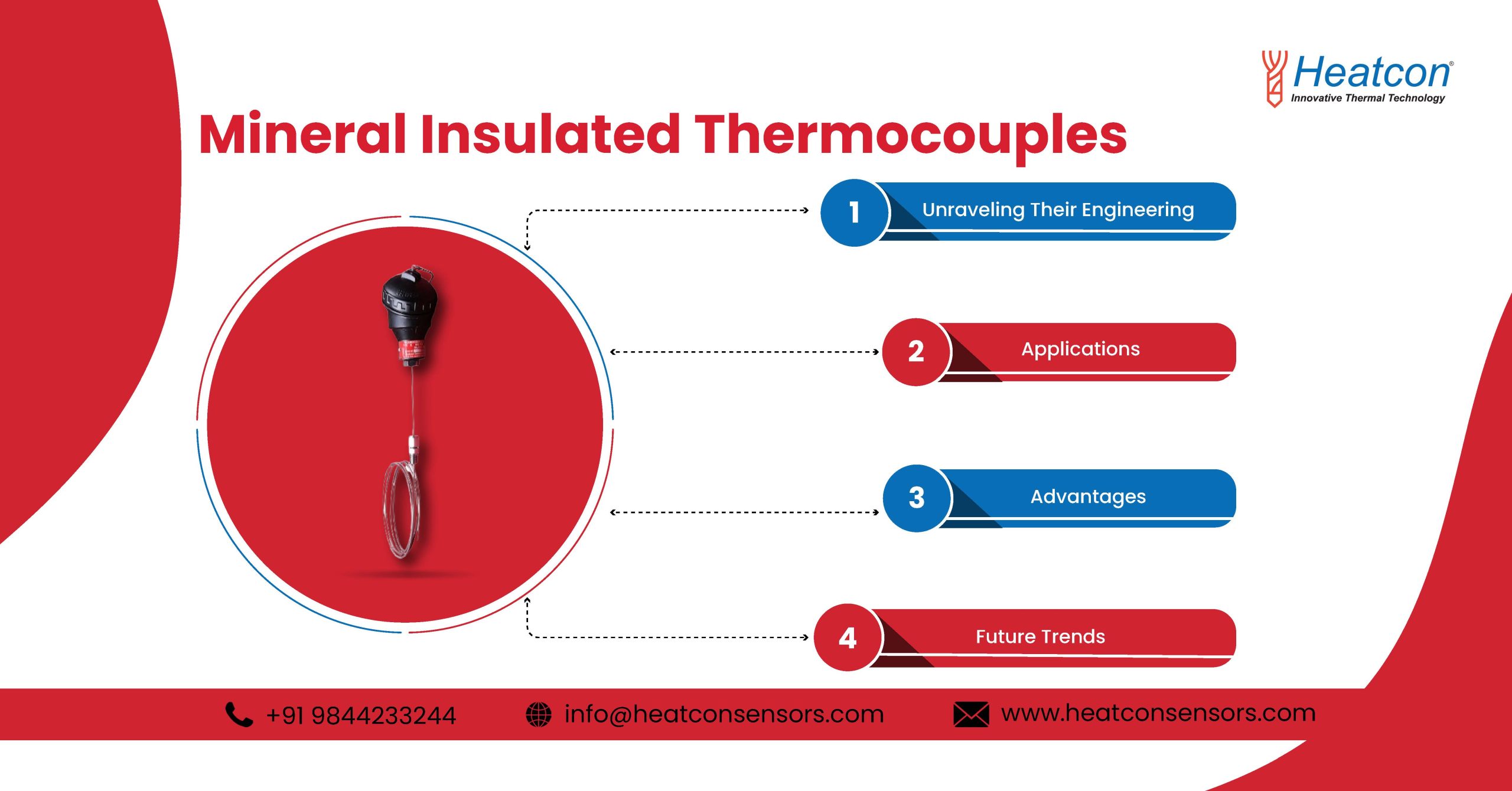

Heatcon Sensors designs and manufactures customized Pt100 temperature sensors for immersion, surface, and air sensing applications. Whether your requirement is for a hygienic tri-clamp fitting in a pharmaceutical cleanroom or a mineral insulated probe for high-pressure petrochemical service, Heatcon Sensors delivers tailored engineering solutions.

Why are precision RTDs critical in regulated industries?

Precision RTDs are engineered for enhanced measurement accuracy and minimal tolerance deviations. In regulated industries such as pharmaceuticals, aerospace, and specialty chemicals, process validation depends heavily on accurate temperature profiling.

Temperature deviations of even 1°C can:

- Compromise product quality

- Trigger batch rejection

- Cause safety shutdowns

- Result in financial losses

Heatcon Sensors manufactures precision RTDs using high-grade platinum elements and stringent quality control measures. Each sensor can be supplied with calibration certificates traceable to national and international standards, supporting compliance in India, UAE, Saudi Arabia, Kuwait, Bahrain, Germany, Indonesia, Russia, South Korea, and the United States.

What are custody transfer temperature sensors and where are they used?

Custody transfer temperature sensors are specialized industrial RTDs used in transactions involving measurable commodities such as oil, gas, and chemicals. Since these transactions involve high financial value, precise temperature measurement ensures accurate volume and density calculations.

In custody transfer applications, even minor inaccuracies can result in significant revenue discrepancies. Custody transfer temperature sensors are therefore designed for:

- High accuracy and repeatability

- Robust construction for hazardous zones

- Compliance with international oil and gas standards

- Long-term stability in corrosive environments

Heatcon Sensors provides engineered custody transfer temperature sensors built to withstand extreme operational conditions. With global logistics support, these sensors can be delivered to refinery projects in Saudi Arabia, LNG terminals in South Korea, petrochemical complexes in Germany, and energy plants across India and the US.

How do industrial RTDs enhance process reliability?

Industrial RTDs are rugged temperature sensors designed to function in harsh operating environments such as high vibration, corrosive chemicals, and extreme heat. They form the backbone of automation systems in industries including cement, steel, power generation, food processing, and oil & gas.

Industrial RTDs offer:

- Durability under mechanical stress

- Resistance to oxidation and corrosion

- Compatibility with transmitters and control panels

- Minimal maintenance requirements

Heatcon Sensors manufactures industrial RTDs with customized thermowells, head assemblies, and transmitter integration options. Clients can specify thread types, flange standards, protection class, and wiring configurations. This customization ensures perfect alignment with project specifications and international compliance standards.

Why choose Heatcon Sensors for platinum RTD sensors?

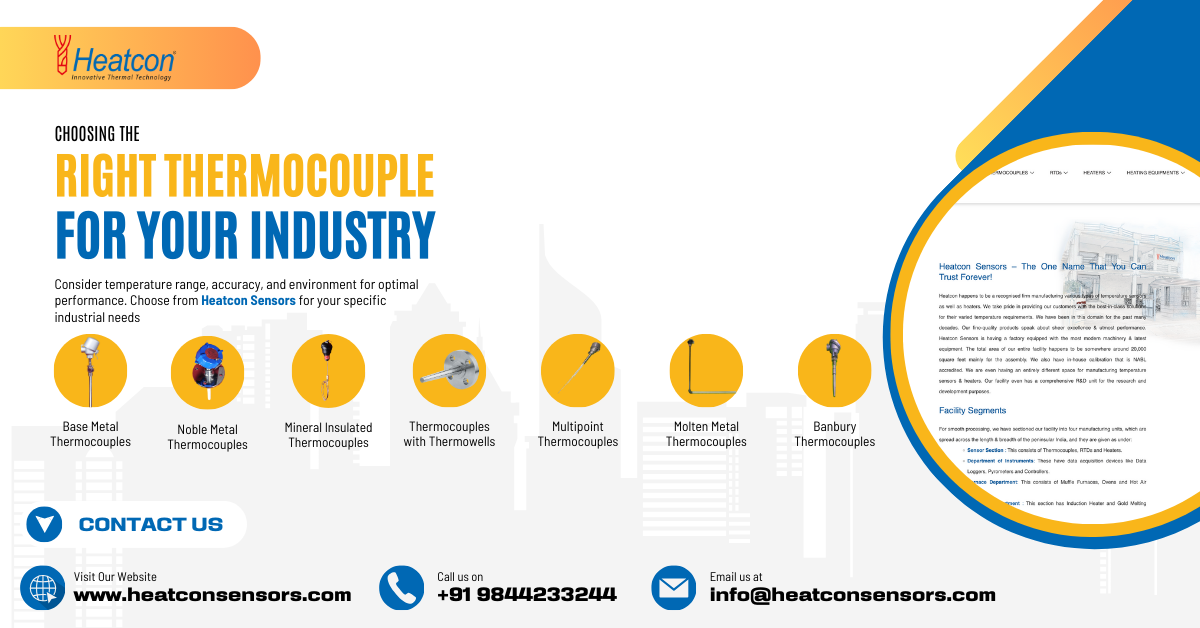

Heatcon Sensors is a temperature sensor manufacturer based in India, specializing in customized platinum RTD sensors, Pt100 temperature sensors, precision RTDs, custody transfer temperature sensors, and industrial RTDs for critical applications worldwide.

Key advantages include:

- Custom manufacturing tailored to exact industrial specifications

- In-house engineering and testing facilities

- Fast turnaround for domestic and international supply

- Global shipping capabilities across Asia, Europe, Middle East, and North America

- Integration expertise with heat generating equipment

Beyond sensors, Heatcon Sensors also manufactures heat generating equipment including furnaces, ovens, hot air blowers, electric furnaces, industrial heaters, laboratory furnaces, high density cartridge heaters, tubular heaters, and customized heating systems. This integrated expertise ensures that temperature sensing and heat generation systems function in perfect harmony.

Applications across industries and geographies

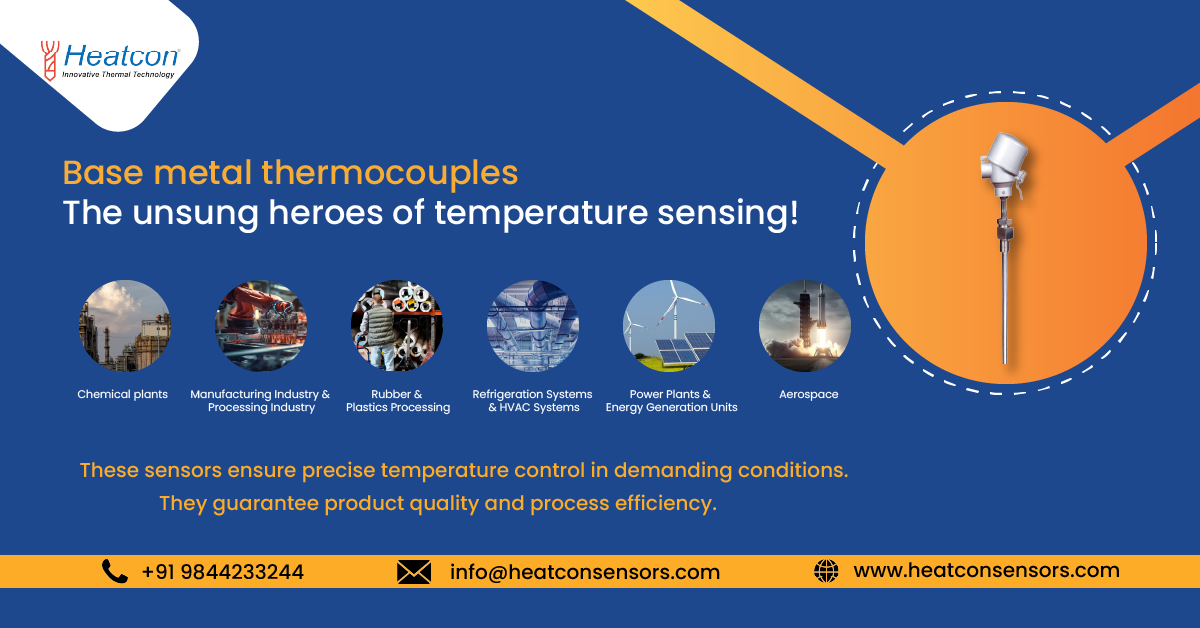

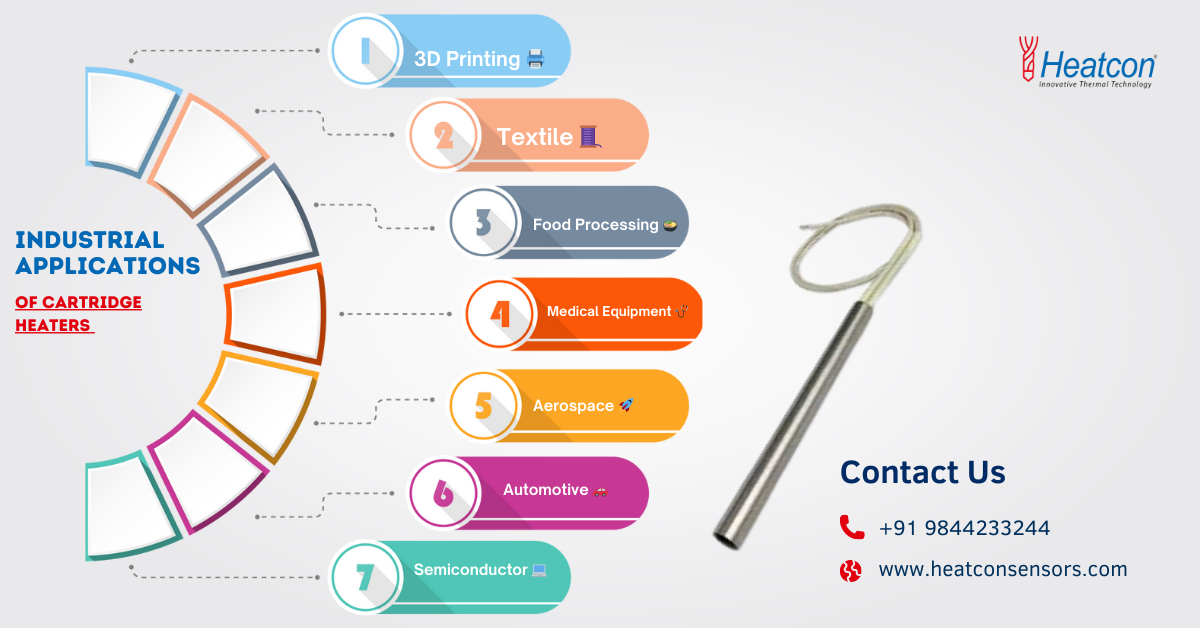

Heatcon Sensors serves diverse industries including:

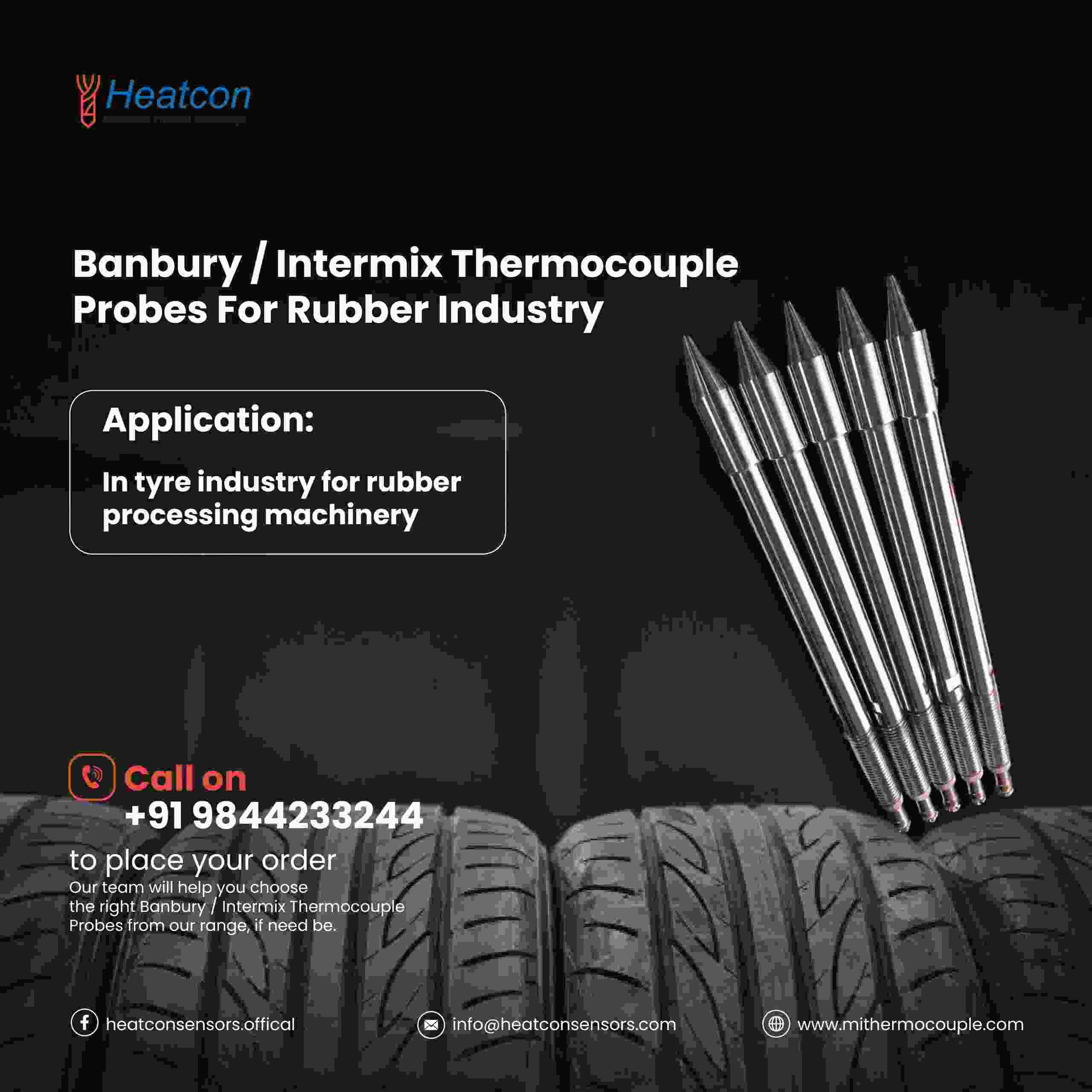

- Oil & Gas – Refining, LNG, petrochemicals

- Pharmaceuticals – Sterilization and validation

- Power Generation – Turbine and boiler monitoring

- Steel & Cement – Kiln and furnace temperature control

- Food Processing – Hygienic process monitoring

- Laboratories & Research Facilities

With a global supply network, Heatcon Sensors provides temperature sensors to clients in India, United States, UAE, Saudi Arabia, Kuwait, Bahrain, Germany, Indonesia, Russia, and South Korea. Custom documentation, export compliance, and packaging standards ensure smooth international project execution.

What happens if you compromise on temperature sensing quality?

In critical industries, inaccurate temperature data can lead to:

- Equipment damage

- Unplanned shutdowns

- Regulatory penalties

- Loss of product integrity

- Significant financial setbacks

Choosing substandard sensors may appear economical initially but often results in higher lifecycle costs. High-quality platinum RTD sensors manufactured by Heatcon Sensors ensure stability, reliability, and long-term operational efficiency.

About Heatcon Sensors

Heatcon Sensors is an Indian manufacturer specializing in temperature sensors and heat generating equipment for industrial applications. The company designs and supplies customized platinum RTD sensors, Pt100 temperature sensors, precision RTDs, custody transfer temperature sensors, and industrial RTDs engineered for critical process control. With a commitment to engineering excellence and global delivery capabilities, Heatcon Sensors supports industries requiring dependable thermal measurement and heating solutions.

To discuss your project requirements or request a custom quote:

- Submit your information at https://heatconsensors.com/contact-us/

- Leave a message through the WhatsApp interface on the website

- Call +91 9164833027 or +91 9844233244 for immediate assistance

When process accuracy defines your success, your temperature sensors cannot be an afterthought. Partnering with Heatcon Sensors ensures your systems operate with precision, compliance, and confidence—anywhere in India or across the globe.

Frequently Asked Questions – Platinum RTD Sensors for Critical Process Control

platinum RTD sensors are widely preferred in critical process control because of their exceptional accuracy, repeatability, and long-term stability. Platinum provides a highly stable and nearly linear resistance-to-temperature relationship, ensuring reliable measurements across a broad operating range.

Heatcon Sensors designs these sensors with rugged sheaths, vibration resistance, and superior insulation integrity to ensure dependable performance in demanding industrial environments such as oil & gas, pharmaceuticals, and power generation.

Pt100 temperature sensors are RTD elements that have a resistance of 100 ohms at 0°C. They are known for high accuracy, excellent repeatability, and minimal drift compared to many thermocouples.

Heatcon Sensors manufactures Pt100 temperature sensors in 2-wire, 3-wire, and 4-wire configurations to reduce lead resistance errors and enhance measurement precision in automated process control systems.

precision RTDs are engineered with tight tolerance classes to ensure minimal deviation from standardized resistance-temperature curves. They are commonly used in calibration laboratories, pharmaceutical manufacturing, semiconductor production, and research facilities.

Heatcon Sensors supplies precision RTDs compliant with IEC standards and offers optional calibration certificates for traceability and regulatory compliance.

industrial RTDs are designed for durability and consistent performance in high vibration, high pressure, and corrosive process conditions. Their robust construction ensures stable temperature measurement even under mechanical stress.

Heatcon Sensors provides industrial RTDs with thermowells, mineral insulated cables, and customized mounting configurations to enhance safety and simplify maintenance.

custody transfer temperature sensors are used in applications where temperature measurement directly affects financial transactions, such as oil and gas transfer operations. Even slight inaccuracies can result in significant commercial discrepancies.

Heatcon Sensors engineers high-accuracy custody transfer temperature sensors to ensure reliable compensation in flow measurement systems and compliance with stringent industry standards.

Yes. Heatcon Sensors offers customized configurations based on specific application requirements. This includes specialized sheath materials, explosion-proof enclosures, fast response designs, and integrated transmitters.

The engineering team works closely with clients to ensure every solution aligns with mechanical, thermal, and regulatory demands.

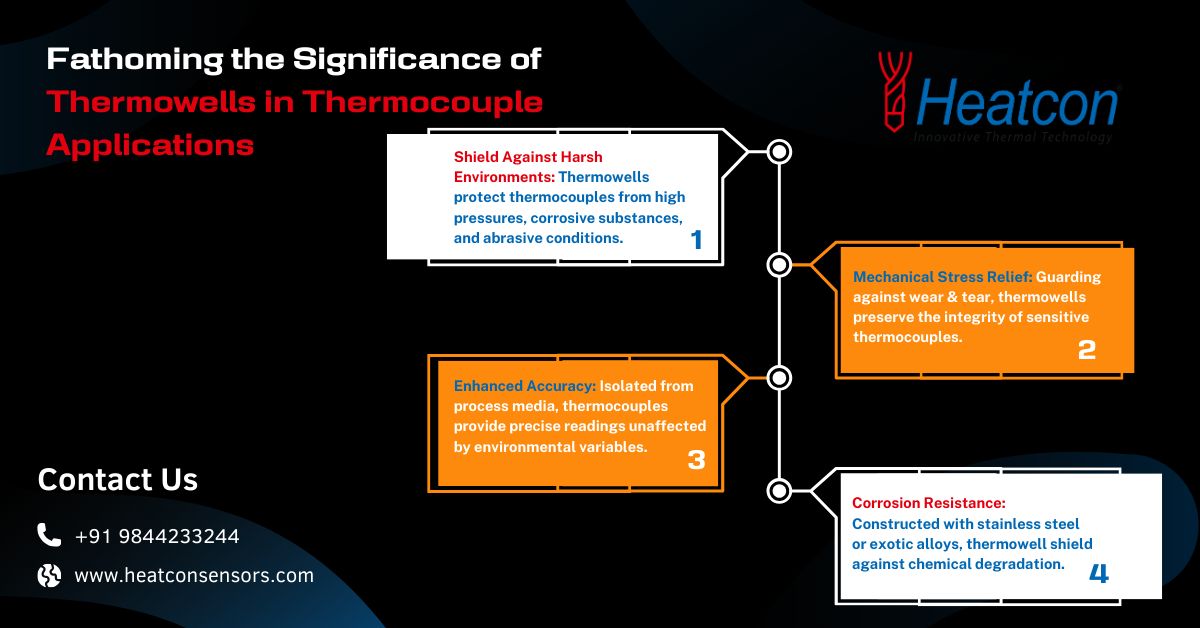

Correct immersion length, suitable thermowell selection, and appropriate wiring configuration significantly impact measurement accuracy and sensor lifespan.

Heatcon Sensors provides installation guidance and technical documentation to help clients maintain optimal performance and extend sensor life in critical process systems.