Common issues with cartridge heaters

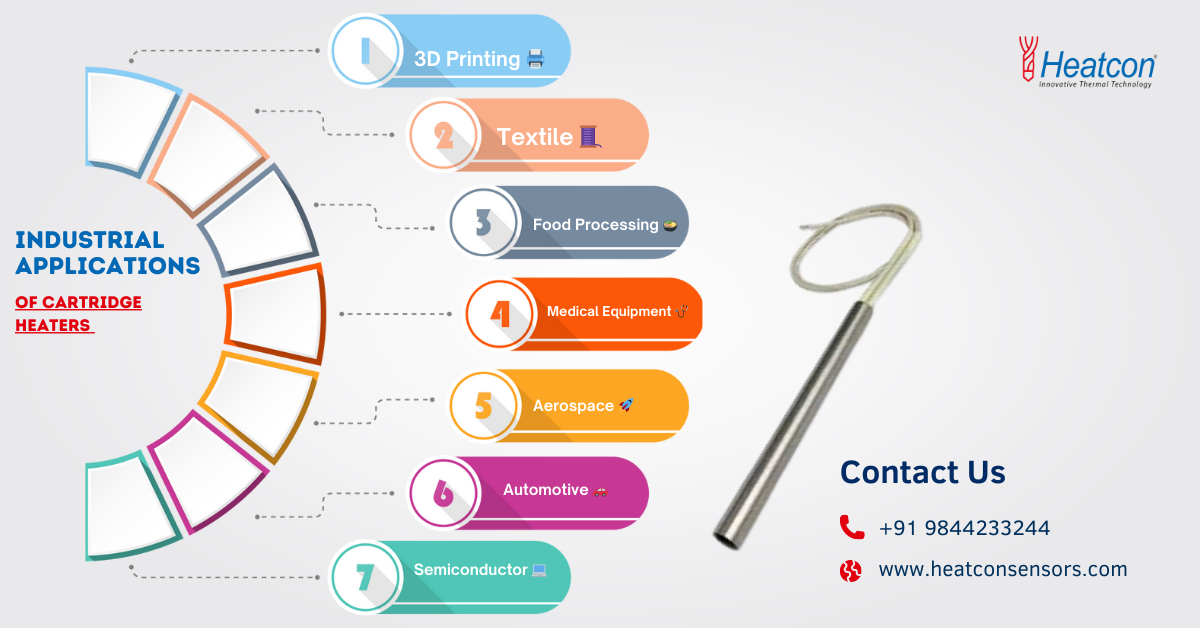

Cartridge heaters are widely used in various industries for heating molds, dies, and other equipment. Despite their reliability, they face several common issues with cartridge heaters that can disrupt operations. These include improper installation, material degradation, and electrical malfunctions. Identifying these challenges early is key to maintaining system efficiency.Identifying cartridge heater problems

Some of the most frequent cartridge heater problems include overheating, electrical failure, and physical damage. Operators often notice reduced heating efficiency or complete heater failure. Understanding these problems helps in implementing effective solutions.Troubleshooting cartridge heaters

When faced with performance issues, troubleshooting cartridge heaters should begin with a systematic approach. Check the power supply, inspect the heater for visible damage, and test the resistance of the heating element. Using appropriate diagnostic tools can pinpoint the issue effectively.Understanding cartridge heater failure reasons

Key cartridge heater failure reasons include overheating, poor maintenance, and exposure to moisture. High watt densities can also contribute to burnout, as they create excessive thermal stress on the heating element.Cartridge heater maintenance

Regular cartridge heater maintenance is crucial to ensure their longevity. This involves cleaning the heater, checking for corrosion, and replacing worn-out components. Proper maintenance not only improves performance but also reduces downtime.How to extend cartridge heater lifespan

To extend cartridge heater lifespan, operators should focus on proper installation, ensure tight fitting, and avoid exceeding the recommended operating temperature. Additionally, regular monitoring of the heater’s performance can help identify issues before they escalate.Issues Caused by improper fit in cartridge heaters

An improper fit in cartridge heaters can lead to inefficient heat transfer, overheating, and premature failure. Ensuring the heater fits snugly into its housing is essential for optimal thermal conductivity and operational efficiency.Addressing high watt density problems

High watt density problems occur when the wattage of the heater exceeds the design limits of the application. This can cause localized overheating, leading to element burnout and reduced heater lifespan. Heatcon Sensors offers solutions to manage watt density effectively.Preventing cartridge heater overheating

Cartridge heater overheating is a common issue caused by improper power settings or inadequate heat dissipation. Installing thermal controls and monitoring system performance can help prevent overheating.Dealing with moisture damage to cartridge heaters

Moisture damage to cartridge heaters often occurs in environments with high humidity. Moisture infiltration can lead to short circuits and corrosion. Using moisture-resistant materials and proper sealing techniques can mitigate this issue.Impact of faulty temperature sensors in heaters

Faulty temperature sensors in heaters can result in inaccurate temperature control, causing overheating or underheating. Regular calibration and replacement of sensors are essential to maintain system accuracy.Signs of damaged heating elements

Damaged heating elements can be identified by irregular temperature output, visible wear, or complete failure to heat. Timely replacement is necessary to restore efficient operation.Why is my cartridge heater not working?

“Why is my cartridge heater not working?” is a common question faced by operators. The reasons could range from electrical failure and damaged elements to improper fit or overheating. A thorough diagnostic process is required to identify and resolve the issue.How to troubleshoot cartridge heater failure?

“How to troubleshoot cartridge heater failure?” involves checking the electrical connections, inspecting the element for visible damage, and using a multimeter to test continuity. Documenting recurring issues can also help in refining troubleshooting techniques.Common causes of cartridge heater malfunction

The common causes of cartridge heater malfunction include poor installation, exposure to contaminants, and electrical faults. Regular inspection and adherence to operating guidelines can help minimize these issues.Tips to prevent cartridge heater issues

Tips to prevent cartridge heater issues include using high-quality heaters from manufacturers like Heatcon Sensors, ensuring proper installation, and conducting routine maintenance. Investing in preventive measures ensures long-term efficiency and cost savings.Cartridge heater lifespan and maintenance tips

To maximize cartridge heater lifespan and maintenance tips, operators should follow a comprehensive maintenance schedule. Clean the heaters regularly, monitor operating conditions, and replace worn-out components promptly. Working with experts like Heatcon Sensors ensures access to reliable and durable heating solutions. For customized cartridge heater solutions tailored to your industrial needs, contact Heatcon Sensors. With decades of expertise, we ensure optimal performance and longevity for all your heating requirements.Common Cartridge Heater Issues: FAQ

Common issues include overheating, improper fit, high watt density, and moisture damage, which can reduce efficiency and lifespan.

Frequent problems include physical damage, electrical failure, and faulty temperature sensing, leading to unreliable operation.

Start by inspecting for visible damage, checking electrical connections, and measuring resistance using a multimeter.

Excessive heat buildup, moisture ingress, and poor maintenance are the primary causes of failure.

Maintenance ensures consistent heating performance and extends heater life by preventing premature damage.

Proper installation, moisture protection, controlled temperatures, and regular inspections help extend lifespan.

An improper fit causes uneven heating, poor heat transfer, and higher energy consumption.

High watt density leads to localized overheating when heat cannot dissipate efficiently, reducing heater life.

Overheating is caused by inadequate heat dissipation, excessive voltage, or poor temperature control.

Use sealed heaters, dry storage, and moisture-resistant designs for humid environments.

Faulty sensors cause inaccurate readings, leading to overheating or underheating.

Signs include reduced heating, visible cracks, or complete failure to heat.

Possible reasons include power supply issues, damaged elements, or incorrect installation.

Check voltage supply, test resistance, and inspect physical condition to identify failures.

Wear and tear, environmental exposure, and improper usage are common causes.

Correct sizing, proper installation, routine inspections, and quality heaters reduce issues.

Operate within rated limits, maintain cleanliness, and replace components proactively.