Over 70% of industrial thermocouple installations rely on the K type thermocouple due to its reliability and wide temperature range. Its composition and materials directly influence how effectively it performs across high and low temperatures. Understanding these materials helps industries ensure precision, stability, and durability in demanding environments. This article explores what goes into a K type thermocouple composition and why Heatcon Sensors is a trusted manufacturer for custom-built temperature sensors worldwide.

What is a K type thermocouple and how does it work?

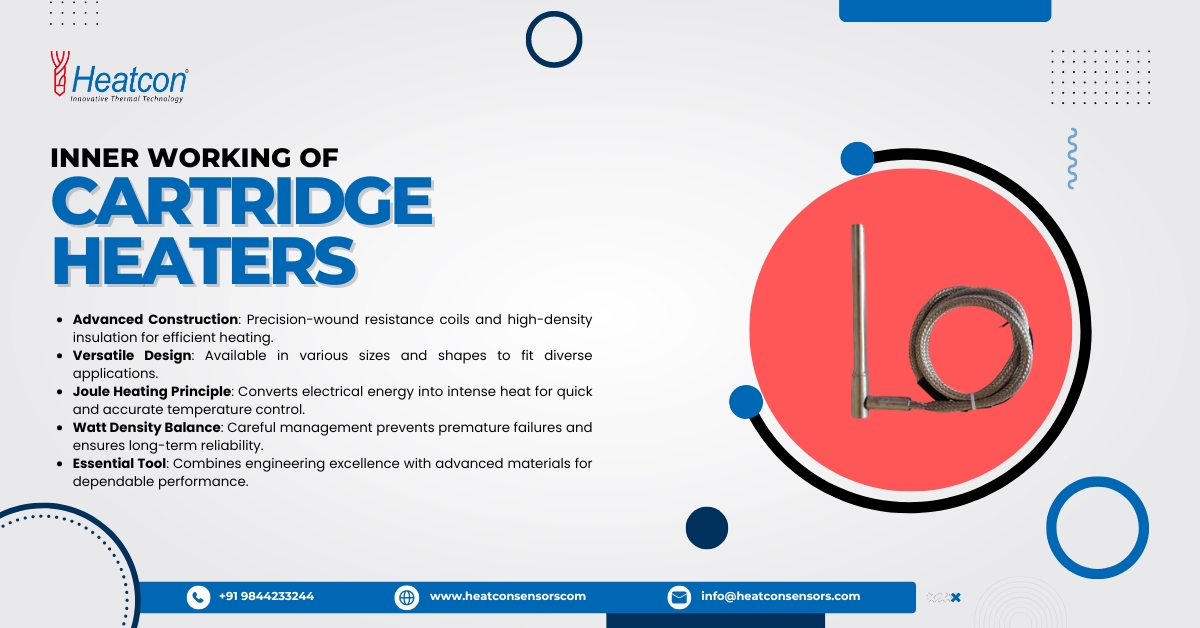

A K type thermocouple is a temperature-sensing device made by joining two dissimilar metals that generate a voltage when exposed to temperature differences. This voltage, known as the Seebeck effect, is directly proportional to temperature. It is one of the most versatile and widely used thermocouple types in industrial applications such as furnaces, ovens, and high-density cartridge heaters.

The effectiveness of the thermocouple depends largely on the integrity and composition of its metals—hence, the K type thermocouple composition plays a critical role in determining performance accuracy and lifespan.

Understanding the K type thermocouple composition

The K type thermocouple composition consists of two key alloys: Chromel and Alumel. The positive leg is made of chromel, which is approximately 90% nickel and 10% chromium, while the negative leg is composed of alumel, containing around 95% nickel and small amounts of aluminium, manganese, and silicon. Together, they form a balanced pair that ensures precise thermoelectric response across a wide temperature range.

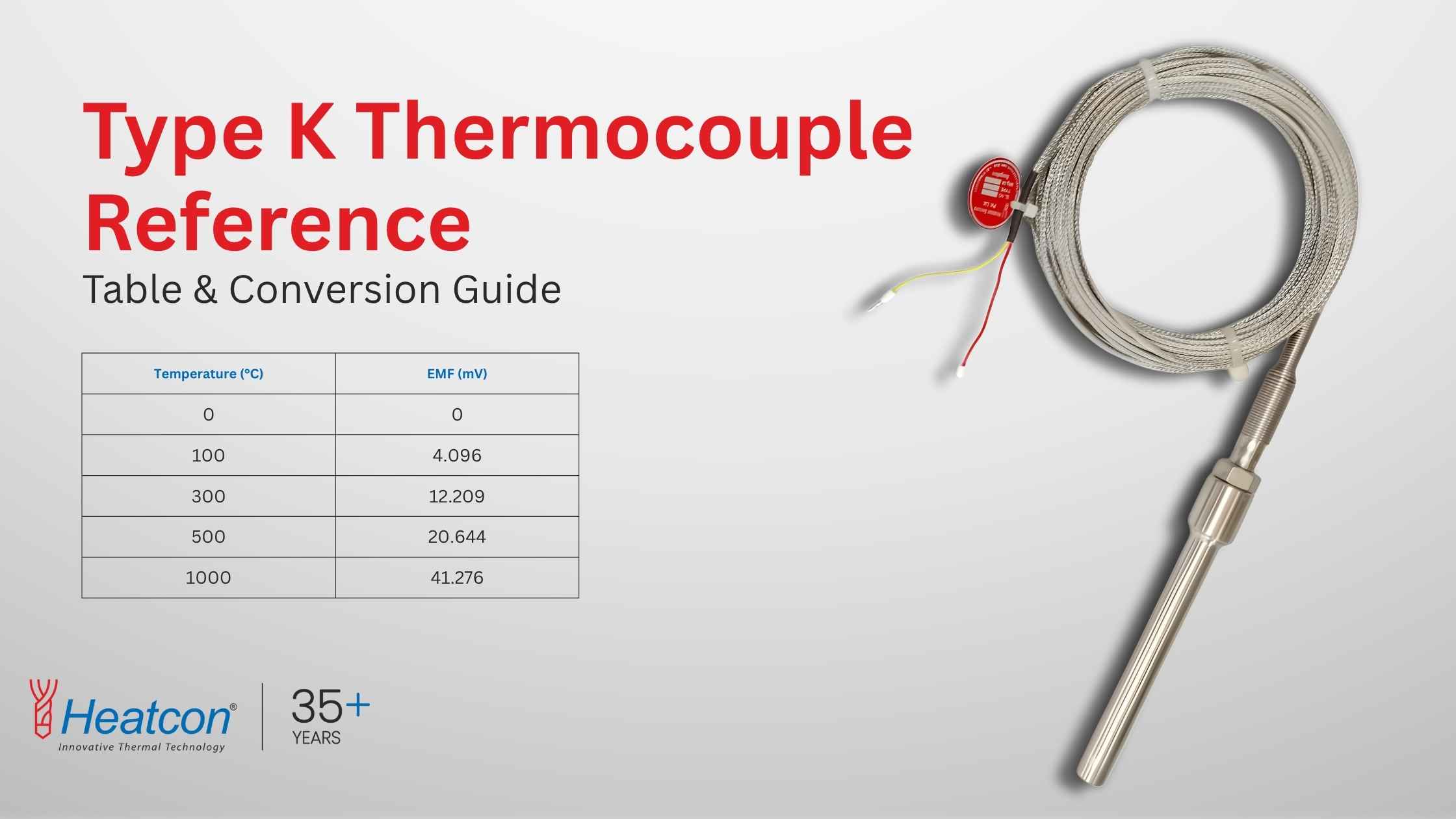

| Leg | Material composition |

|---|---|

| Positive (Chromel) | Nickel-Chromium Alloy (~90% Nickel, 10% Chromium) |

| Negative (Alumel) | Nickel-Aluminium Alloy (~95% Nickel, plus Aluminium, Manganese, and Silicon) |

This nickel-based pairing ensures strength, corrosion resistance, and stable output even under thermal stress. The combination of nickel-chromium and nickel-aluminium allows consistent measurement from -200°C to +1260°C, making it the go-to thermocouple type for multiple industries.

Why these specific alloys matter

The choice of nickel-chromium and nickel-aluminium alloys isn’t arbitrary—they were engineered for performance and resilience. Nickel-chromium (used in chromel) provides superior oxidation resistance and mechanical stability, while nickel-aluminium (used in alumel) enhances durability and temperature consistency.

- High temperature tolerance: Operates efficiently from cryogenic levels up to 1260°C.

- Resistance to oxidation: Performs exceptionally in oxidizing environments, including furnaces and ovens.

- Long-term stability: Maintains calibration even under continuous high-heat exposure.

These qualities make the K type thermocouple an affordable yet robust alternative to precious metal sensors like type R or S thermocouples, particularly in industrial heating applications.

Protective sheath materials in K type thermocouples

The external sheath is just as important as the inner alloys. It shields the thermocouple wires from corrosive environments and mechanical wear. Common sheath materials include SS 316, SS 310, Inconel 600, Inconel 800, and Alloy 160 HR. Each of these provides specific advantages depending on temperature range and chemical exposure.

| Sheath material | Approx. temperature limit | Best suited for |

|---|---|---|

| SS 316 | Up to 850°C | General industrial use, corrosion-resistant. |

| SS 310 | Up to 1000°C | High-temperature ovens and heaters. |

| Inconel 600 | Up to 1260°C | Oxidizing and high-heat furnace environments. |

| Inconel 800 | Up to 1300°C | High-stress, long-life operations. |

| Alloy 160 HR | Above 1300°C | Extreme temperature and heavy-duty industrial systems. |

These materials not only extend the lifespan of thermocouples but also ensure that readings remain stable, even in conditions of fluctuating temperature or chemical exposure.

Heatcon Sensors’ expertise in customized manufacturing

Heatcon Sensors is one of India’s most trusted manufacturers of customized temperature sensors and industrial heating systems. The company specializes in precision-engineered thermocouples, RTDs, and related heat-generating equipment. Whether you require a single sensor or large-scale production, Heatcon offers custom manufacturing to meet exact industrial needs.

Key offerings include:

- Custom-built K type thermocouples with chromel and alumel conductors.

- RTDs and other precision temperature sensors.

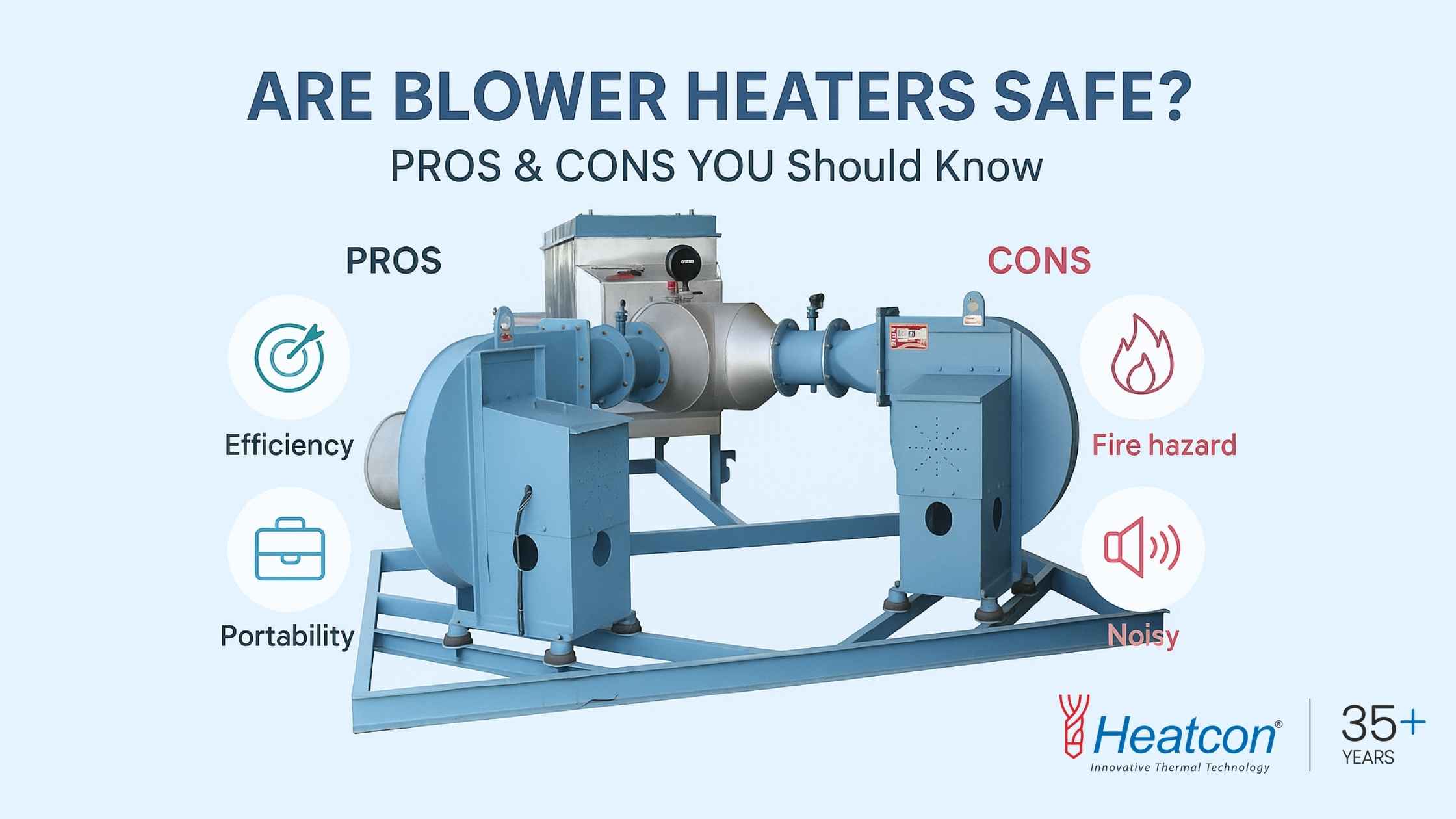

- Industrial furnaces, ovens, and hot air blowers.

- Electric furnaces, high-density cartridge heaters, and custom heat assemblies.

With capabilities extending across India and global markets including the United States, UAE, Germany, South Korea, Saudi Arabia, Russia, Bahrain, Kuwait, and Indonesia, Heatcon Sensors ensures timely delivery and technical precision across industries.

Choosing the right thermocouple for your application

To achieve optimal performance, it’s important to select the correct materials and design configuration. Consider the following before installation:

- Temperature range: Ensure compatibility with your process’s maximum and minimum temperatures.

- Atmosphere type: Match sheath material to oxidizing or reducing environments.

- Accuracy requirements: Choose a calibration that meets your precision standards.

- Response time: Factor in sensor diameter and insulation materials.

- Maintenance and replacement cycles: Opt for materials like Inconel or Alloy 160 HR for high-endurance needs.

By consulting with Heatcon Sensors’ engineering team, you can ensure that every thermocouple assembly—whether with SS 316, SS 310, or Inconel 600 sheaths—meets your operational demands.

Global applications of K type thermocouples

K type thermocouples are used in virtually every industry that involves heat. Their versatility extends to metal processing, petrochemical refining, aerospace component testing, and energy generation. Because they balance cost-efficiency and high performance, they’re often the first choice for process engineers worldwide.

About Heatcon Sensors

Based in Bengaluru, India, Heatcon Sensors has become synonymous with innovation in temperature measurement and heat-generating technology. With decades of expertise, the company designs and delivers precision-engineered RTDs, thermocouples, and industrial heaters that meet international standards. Their solutions are trusted by industries across manufacturing, automotive, aerospace, power, and process control sectors.

For inquiries or custom solutions, you can:

- Submit your information via the form at https://heatconsensors.com/contact-us/.

- Message directly through the WhatsApp interface on the website.

- Call +91 9164833027 or +91 9844233244 for immediate assistance.

To summarize

The K type thermocouple composition—built from chromel and alumel, with protective sheaths of SS 316, SS 310, Inconel 600, Inconel 800, or Alloy 160 HR—remains one of the most reliable configurations for industrial temperature measurement. Choosing the right combination of alloys and protective materials ensures durability and accuracy in even the harshest environments.

Heatcon Sensors empowers industries with precision-manufactured thermocouples and heat-generating systems that are globally recognized for their performance. Investing in the right materials and expert engineering isn’t just a choice—it’s the key to long-term operational excellence. Don’t compromise on accuracy. Choose Heatcon Sensors today for your industrial temperature and heating solutions.

K type thermocouple composition & materials — frequently asked questions

K type thermocouple composition refers to the specific pairing of two dissimilar nickel-based alloys that generate a stable thermoelectric voltage across a wide temperature range. Getting the composition right ensures repeatable accuracy, long life in harsh atmospheres, and predictable response—key for furnaces, ovens, heat-treatment lines, and process controls that cannot afford drift or downtime.

Need an application-matched probe? Heatcon Sensors engineers specify the right conductors, insulation, sheath, and junction type to your environment for consistent results shift after shift.

Type K pairs chromel (positive leg) with alumel (negative leg) to balance sensitivity, oxidation resistance, and cost. This combination offers stable output from cryogenic levels to elevated temperatures, making it a dependable choice for general-purpose industrial measurement without resorting to expensive noble-metal systems.

The positive conductor is a nickel-chromium alloy that resists oxidation at high temperatures, while the negative conductor is a nickel-aluminium alloy formulated for stability and durability. Together, they produce a dependable Seebeck voltage across demanding ranges and atmospheres, supporting precise control in thermal processes.

Sheath selection protects the conductors and determines service life:

- SS 316 – corrosion-resistant choice for general industrial service and moderate heat.

- SS 310 – higher temperature stainless for ovens and heat-treat zones.

- Inconel 600 – excellent high-temperature oxidation resistance for furnace duty.

- Inconel 800 – robust performance and creep resistance in prolonged high-heat exposure.

- Alloy 160 HR – engineered for extreme duty cycles where longevity is critical.

Heatcon Sensors matches sheath metallurgy to atmosphere (oxidizing/reducing), thermal cycling, and mechanical stress to extend probe life and maintain calibration.

Heatcon Sensors designs Type K probes for applications from cryogenic monitoring to elevated furnace conditions, tailoring wire gauges, insulation, and sheath (e.g., SS 316, SS 310, Inconel 600, Inconel 800, Alloy 160 HR) to your setpoints, ramp rates, and dwell durations. The result is a probe that stays stable through real-world cycles rather than just lab ratings.

Yes. Heatcon Sensors builds grounded, ungrounded, or exposed junctions; mineral-insulated cables; braided or armored leads; adjustable compression fittings; and flanged or threaded inserts. Each assembly is engineered to your mounting method, response-time needs, insulation class, and environmental chemistry so your readings remain steady and noise-free.

Pick grounded for fast response and robust mechanical integrity; pick ungrounded to reduce electrical noise when measuring near drives or power electronics. Heatcon Sensors recommends junctions based on controller input filtering, sheath choice, and the electrical environment to balance responsiveness with signal quality.

Share your temperature range, atmosphere, mounting details, preferred sheath, and cable options. You can submit specifications via the form at heatconsensors.com/contact-us/, message through the WhatsApp interface on the Heatcon Sensors website, or call +91 9164833027 / +91 9844233244 for immediate assistance.