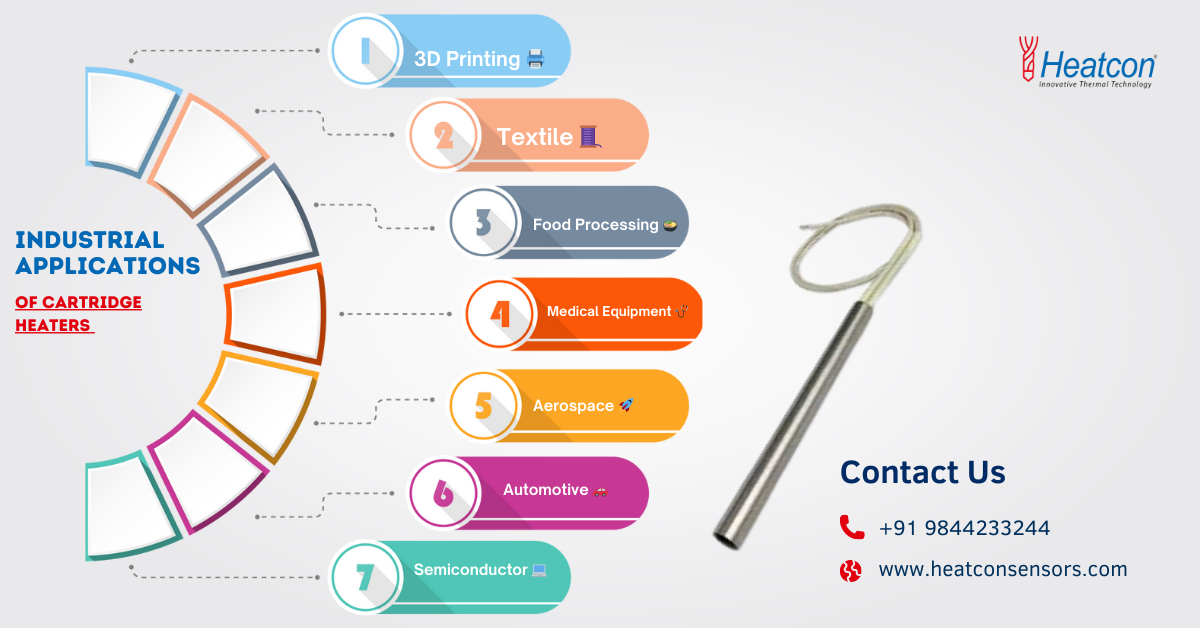

Cartridge heaters are quite resourceful and can be utilised in a myriad of industrial processes owing to their capability of providing localized heating in a compact form. The global market for Cartridge Heaters is projected to rise at a high rate in the years to come (2023 to 2030), and this is chiefly driven by the increasing demand for these heaters in the Woodworking Industry, Pharmaceuticals Industry, Automotive Industry, Paper-Making Industry, Electronic Industry & Electrical Industry, among others. Below are some specific industrial applications of cartridge heaters:

3D Printing

In the 3D printing domain, these heaters are utilised for heating the printing nozzles. Such controlled heating helps in the melting & extrusion of filament materials (including ABS and/or PLA), thus ensuring accurate printing (layer-by-layer).

Textile Industry

Cartridge heaters find their use in textile machinery for the purpose of heating elements in difficult processes including embossing, heat sealing, laminating, etc. These heaters facilitate precise temperature control in the segment of textile manufacturing.

Food Processing

Firms use these heaters in food processing equipment for different applications like sealing bars, heating plates, extrusion dies, etc. These heaters help in the hygienic heating & processing of various food products.

Medical Equipment

Medical firms use these heaters in medical equipment like autoclaves, sterilizers, diagnostic devices, etc., for fluid containers, heating chambers, and other such components that need controlled temperatures.

Oil & Gas Industry

People use these heaters in equipment including valves, pipelines’ heating jackets, tanks, etc., in the O & G industry for the prevention of freezing or the maintenance of fluid viscosity in cold environments.

Aerospace Industry

These heaters also find their application in aerospace equipment for different tasks including the heating of moulds & tools in the manufacturing processes of composite material, and also in aircraft’s de-icing systems.

Automotive Industry

The automotive manufacturing industry uses these heaters for several tasks including the heating of dies & molds in the production of plastic & rubber components, etc., and also for the preheating of engine parts while assembling.

Packaging Machinery

Industries use these heaters in the packaging machinery in cutting, sealing, & forming applications. Cartridge heaters provide effective heat transfer here for the sealing of packaging materials like plastic films & foils etc.

Semiconductor Industry

In the semiconductor manufacturing equipment, companies use these heaters for different processes including wire bonding, wafer heating, & die attach, etc. They tend to give precise temperature control, which is quite crucial for the purpose of semiconductor fabrication.

Lab Equipment

These heaters form the integral components of lab equipment like incubators, ovens, environmental chambers, etc. They tend to give steady & consistent heating for different experimental & testing purposes.

Metalworking Industry

In various metalworking processes like die casting & extrusion etc., companies use these heaters for the heating of metal moulds & dies, thus helping in the shaping & forming of different metal parts.

Plastic Injection Moulding

Plastic injection molding machines make use of cartridge heaters for heating the molds. They give accurate & consistent heating, which helps in bringing about the consistent quality of the molded products.

So, these were some common industrial applications of cartridge heaters where they play a significant role in providing controlled & localized heating solutions in varied processes. The compact design, versatility, & efficiency of these heaters make them truly indispensable in a gamut of industry-related processes. At Heatcon Sensors, you can lay your hands on the best products!