In the precision manufacturing world, injection molding is a cornerstone of modern industrial processes. Temperature control plays a critical role in ensuring high-quality output. Enter the high-temperature cartridge heater for injection molding, a revolutionary solution designed to deliver consistent heat, energy efficiency, and long-lasting performance. Whether optimizing existing equipment or building new systems, these heaters are indispensable for maintaining precision and reliability.

Understanding the Role of Cartridge Heaters in Injection Molding

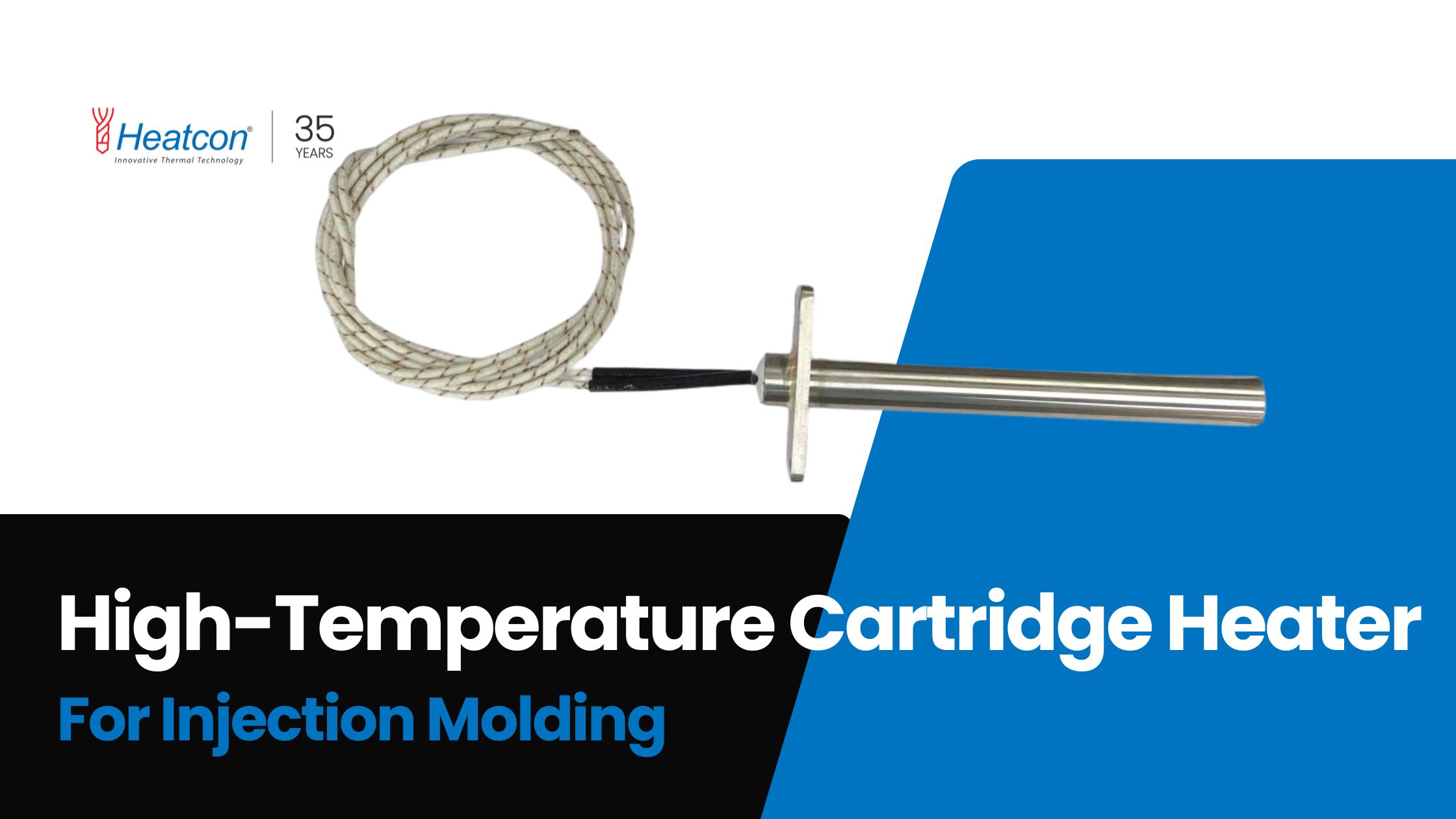

Injection molding requires the melting of polymers to create complex, durable products. This process demands reliable high-temperature heating solutions to maintain the consistency and quality of materials. A high-temperature cartridge heater for injection molding is specifically engineered to meet these requirements, ensuring that the necessary heat is evenly distributed across the mold.

These heaters are also designed to minimize energy consumption, making them an excellent choice for industries striving for sustainability. By integrating an energy-efficient cartridge heater for industrial ovens into the injection molding process, manufacturers can reduce power usage while maintaining optimal performance.

Why Choose a High-Temperature Cartridge Heater?

- Durability: Designed to withstand extreme conditions, these heaters are known as durable cartridge heaters for industry, ensuring a long operational life even in challenging environments.

- Energy Efficiency: Incorporating energy-efficient cartridge heater for industrial ovens principles, they minimize energy waste without compromising performance.

- Precision Heating: Uniform heat distribution ensures consistent product quality, making them a top choice for high-precision applications.

Advanced High-Temperature Heating Solutions

The key to achieving consistent results in injection molding lies in leveraging advanced high-temperature heating solutions. These heaters are built with cutting-edge technology, allowing them to achieve and sustain the exact temperatures required for different polymers. By doing so, they help prevent common issues such as material degradation, uneven molding, and part defects.

Industries that depend on injection molding also benefit from the seamless integration of these heaters with automated systems. This compatibility ensures efficient temperature monitoring and control, further enhancing production outcomes.

Energy Efficiency: A Sustainable Approach

Sustainability is more than a trend; it’s a necessity. Adopting an energy-efficient cartridge heater for industrial ovens in your injection molding process can significantly reduce your energy bills while supporting eco-friendly practices. These heaters are designed with insulation and optimized energy transfer capabilities, ensuring minimal heat loss.

Manufacturers using durable cartridge heaters for industry not only save money but also contribute to reducing their carbon footprint, meeting both economic and environmental goals.

Applications Beyond Injection Molding

While a high-temperature cartridge heater for injection molding is a crucial component in its respective industry, its versatility extends to other applications. These include:

- Packaging machinery

- Medical device manufacturing

- Food processing equipment

- Industrial ovens and kilns

In these settings, high-temperature heating solutions ensure that the desired thermal conditions are met for various processes, increasing efficiency and reliability.

Choosing the Right Manufacturer

Selecting the right manufacturer is vital when investing in a high-temperature cartridge heater for injection molding. Look for companies that offer a blend of innovation, quality, and customer support. Indian manufacturers, in particular, are known for their expertise in delivering durable cartridge heaters for industry, backed by cutting-edge research and stringent quality standards.