What is a heater and what is a blower?

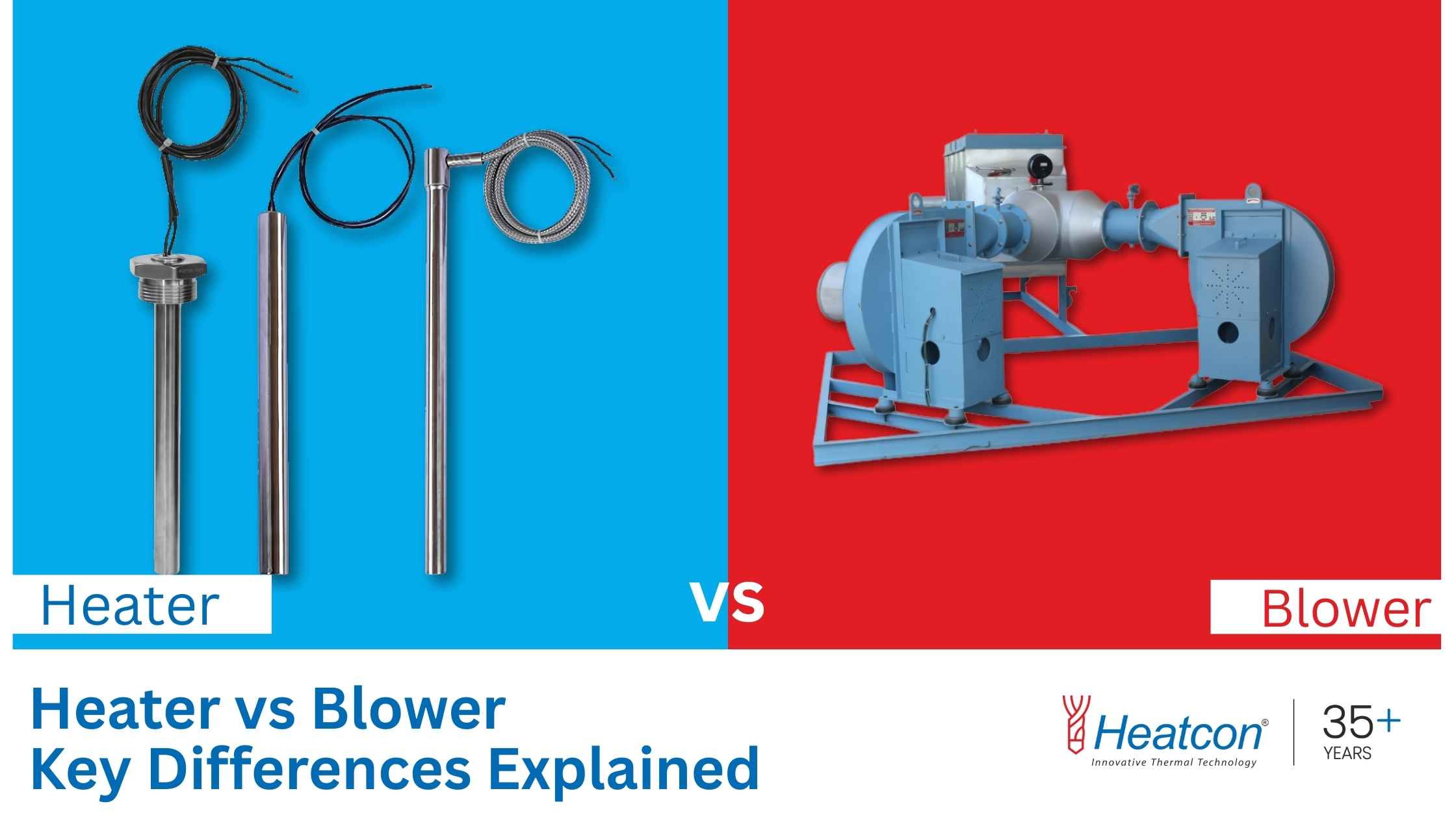

A heater is a device designed to convert electrical, chemical, or mechanical energy into heat energy to warm air, liquids, or surfaces. In contrast, a blower moves air or gas, creating airflow for ventilation or combustion. The blower and heater difference lies in their core functions—while a heater generates heat, a blower circulates air.How does a heater work compared to a blower?

Heaters use resistive elements, combustion, or induction to generate heat. Heatcon Sensors manufactures electric furnaces, high density cartridge heaters, industrial ovens, and custom heating solutions for specialized environments. Blowers, on the other hand, employ impellers and motors to push air. Together, these technologies create effective climate control systems like heaters with blowers that combine heat generation with air circulation.Key differences between heater and blower

- Heat generation vs airflow: A heater generates warmth; a blower moves air.

- Applications: Heaters are used in industrial furnaces, ovens, and RTD calibration setups, whereas blowers support ventilation, cooling, and combustion.

- Components: Heaters use heating elements, while blowers rely on heater blower motor systems and impellers.

- Combined units: Room heaters and blowers integrate both technologies for efficient performance.

Why understanding blower heater best combinations matters

Selecting the blower heater best configuration ensures optimal energy use and temperature control. In industrial setups, pairing Heatcon Sensors’ reliable heaters with precision blowers results in superior performance. For instance, a heater blower fan can evenly distribute heat within a warehouse, ensuring consistent temperatures and reducing energy waste.Heating blower machine advantages in industries

A heating blower machine offers robust solutions for drying, curing, and warming processes. Heatcon Sensors’ engineering expertise allows customization of blowers and heaters to meet unique industrial requirements, from chemical plants in Saudi Arabia to automotive factories in Germany. Customized RTDs manufactured by Heatcon Sensors can monitor temperature changes precisely, ensuring equipment efficiency and product quality.Industrial and domestic applications of heaters and blowers

In domestic settings, room heaters and blowers keep homes warm during winter. In industrial contexts, electric furnaces, hot air blowers, and ovens are essential for manufacturing and research. Heatcon Sensors’ high density cartridge heaters and industrial ovens are renowned for durability and accuracy, making them trusted solutions in India and beyond.Choosing Heatcon Sensors for custom solutions

Heatcon Sensors specializes in manufacturing and supplying:- Custom RTDs and thermocouples for precise temperature monitoring.

- Electric furnaces and industrial ovens for heavy-duty applications.

- Hot air blowers and heating blower machine options for fast drying and ventilation.

- High density cartridge heaters for reliable heat delivery.

How to select between a heater and blower

To decide between a heater and blower, consider your application. If you need to increase temperature, choose a heater. If airflow is your goal, opt for a blower. For combined heating and circulation, heaters with blowers are the preferred choice. Heatcon Sensors’ experts can guide you in selecting or customizing the right equipment for your requirements.Practical scenarios showcasing blower and heater difference

Imagine a manufacturing plant in South Korea requiring consistent drying of painted components. A high-performance heater blower fan ensures the paint cures evenly. Alternatively, an electronics factory in India may require precise airflow without additional heat, making a blower ideal. These examples underline the critical difference between heater and blower in real-world applications.About Heatcon Sensors

Heatcon Sensors is an Indian-based manufacturer specializing in customized temperature sensors and heat-generating equipment. Their products include RTDs, thermocouples, cartridge heaters, electric furnaces, industrial ovens, and hot air blowers. With a reputation for excellence and global delivery capabilities, Heatcon Sensors has become a trusted partner for industries in India, the United States, UAE, Saudi Arabia, and more. To get started:- Submit your information on the form at Heatcon Sensors Contact Page.

- Leave a message on WhatsApp via their website interface.

- Call directly at +91 9164833027 or +91 9844233244 for immediate assistance.

To summarize on heater vs blower

Understanding the difference between heater and blower helps optimize energy use and ensures operational efficiency. Heatcon Sensors provides tailor-made solutions, giving industries and homeowners worldwide confidence in their heating and air movement systems. Whether you need a heating blower machine, heater blower motor, or integrated room heaters and blowers, Heatcon Sensors stands ready to deliver superior quality and performance.Heater vs blower: key differences explained — Frequently asked questions

Below are concise, practical answers to common questions buyers ask when comparing heaters and blowers, with specific guidance on Heatcon Sensors’ custom-engineered solutions and how to choose confidently for industrial and building applications.

Short answer: A heater generates thermal energy; a blower moves air. When combined, you get fast heat distribution and uniform process conditions.

In an industrial line, the difference between heater and blower affects warm-up time, energy use, and quality. Heatcon Sensors designs electric furnaces, high-density cartridge heaters, hot air blowers, and custom RTD/thermocouple measurement to match your throughput, target temperature, and airflow requirements.

Short answer: Heaters set the temperature; blowers distribute it. Optimizing both reduces cycle time and prevents hot/cold spots—saving energy.

Heatcon Sensors balances power density (heater selection) with flow/pressure (blower selection) to minimize overshoot and recirculation losses. This tuned pairing often cuts rework and narrows temperature bands, improving first-pass yield.

Short answer: A heater blower fan is an integrated assembly that pushes warm air into a space or process chamber for quick, even heating.

Applications range from paint curing tunnels and food dehydration to HVAC make-up air. Heatcon Sensors supplies matched fans and heater banks, instrumented by RTDs for tight control and stable throughput.

Short answer: The heater blower motor powers the fan/impeller to move air across the heating element and through ducts or chambers.

Heatcon Sensors helps specify motor power, RPM, and duty cycle to match air velocity and static pressure requirements. Correct sizing prevents noise, bearing stress, and temperature stratification.

Short answer: Choose heaters with blowers when you need fast ramp-up, uniform temperature, and high air changes—such as drying, curing, or heat-shrink tunnels.

Heatcon Sensors integrates high-density cartridge heaters or finned tubular elements with blowers, plus RTD feedback, for consistent results across India, the Middle East, Europe, and the Americas.

Short answer: The blower heater best choice depends on target temperature, airflow rate, static pressure, product geometry, and allowable ramp/soak profiles.

Share your setpoints, line speed, chamber volume, and materials. Heatcon Sensors will size kW, element type, motor power, and control strategy (on/off, SCR, or PID) for balanced performance and longevity.

Short answer: A heating blower machine combines heat generation and high-volume airflow to accelerate moisture removal and thermal penetration.

It is ideal for packaging lines, electronics conformal coating, foundry sand drying, and textiles. Heatcon Sensors custom-builds systems with calibrated RTDs to meet repeatability and audit requirements.

Short answer: Yes—properly sized room heaters and blowers with over-temperature protection, guards, and certified wiring deliver safe, even heating.

For showrooms, warehouses, and workshops, Heatcon Sensors recommends guarded elements, airflow interlocks, and RTD-based cut-outs to meet electrical and occupational safety standards.

Short answer: Heatcon Sensors employs high-density cartridge heaters, finned tubular elements, ceramic infrared emitters, and immersion heaters matched to media and environment.

Bodies and sheaths may use SS304/316/Incoloy 800/840; insulation may be MgO; leads are selected for temperature class. RTDs/thermocouples provide closed-loop control for tight bands.

Short answer: Across India and worldwide, including the UAE, Saudi Arabia, Germany, the United States, Indonesia, South Korea, Russia, Bahrain, and Kuwait.

From design and sensor calibration to shipment and commissioning guidance, Heatcon Sensors supports plant managers and OEMs with documentation and repeatable part numbers for scale-up.

Short answer: Use a heater to raise temperature; use a blower to move air; use a combined module when you need both simultaneously and uniformly.

| Need | Choose | Notes |

|---|---|---|

| Increase temperature quickly | Heater | Match kW to mass, losses, and ramp rate |

| Ventilation/cooling/drying via flow | Blower | Size for CFM and static pressure |

| Uniform heat across volume | Heater + Blower | Control via RTD and PID for consistency |

Heatcon Sensors will translate your line data into a right-sized bill of materials.

Short answer: Precision RTDs reduce overshoot/undershoot, narrow tolerance bands, and stabilize cycles—directly improving throughput and quality.

Calibrated sensors feed reliable data to controllers (on/off, SCR, or PID), enabling safer, more efficient operations in ovens, electric furnaces, and hot air blower assemblies.

Short answer: Yes—Heatcon Sensors engineers modular systems that pair room heaters and blowers with suitable guards, controls, and airflow paths.

You receive drawings, wiring diagrams, and sensor placement recommendations for safe, uniform heating in retail floors, warehouses, or process enclosures.

Short answer: Share target temperatures, media, throughput, chamber size, and utilities. You’ll get a tailored configuration and lead time.

- Submit the form: heatconsensors.com/contact-us/

- Use the WhatsApp widget on the Heatcon Sensors website

- Call: +91 9164833027 or +91 9844233244

From RTDs and thermocouples to electric furnaces, ovens, hot air blowers, and integrated modules, Heatcon Sensors supplies across India and worldwide.