Base metal thermocouples happen to be the primary elements of the highly useful temperature sensing systems, providing affordable & versatile solutions for a gamut of industries. Fathoming the basics of these devices is important for process engineers & specialists alike. Let us take a deep dive into the basics of these sensors to recognise their significance & industrial uses.

Explaining Base Metal Thermocouples: A Beginner’s Guide

At the heart of these base metal thermocouples is the thermoelectric principle. Such a phenomenon happens when 2 dissimilar metals are joined, which tends to create a voltage that is proportional to the temperature difference between the joint & the free end of the metal. For thermocouples made of base metals, combinations such as type J (combining Iron and Constantan) or type K (combining Chromel and Alumel) are normally used.

Advantages of Using Base Metal Thermocouples

- One of the primary benefits of utilising these base metal thermocouples is their broad temperature range. For example, Type J ones can measure from -210 degrees Celsius to 760 degrees Celsius of temperatures, while Type K ones cover an even wider range of -270 degrees Celsius to 1260 degrees Celsius. The versatility of these devices makes them ideal for industrial applications like food processing, manufacturing, & HVAC systems.

- Additionally, these sensors have excellent sensitivity & stability over time, which makes them dependable devices for long standing use. Their sturdiness saves them from environmental influences such as vibration & corrosive atmosphere. This makes them particularly useful for industrial environments where durability is important.

- The use of these tools in practice expects meticulous consideration of factors like installation conditions, accuracy needs, and device compatibility with sensing instruments. Repeated maintenance & appropriate calibration are also important for ensuring precise temperature measurements and extending their shelf life.

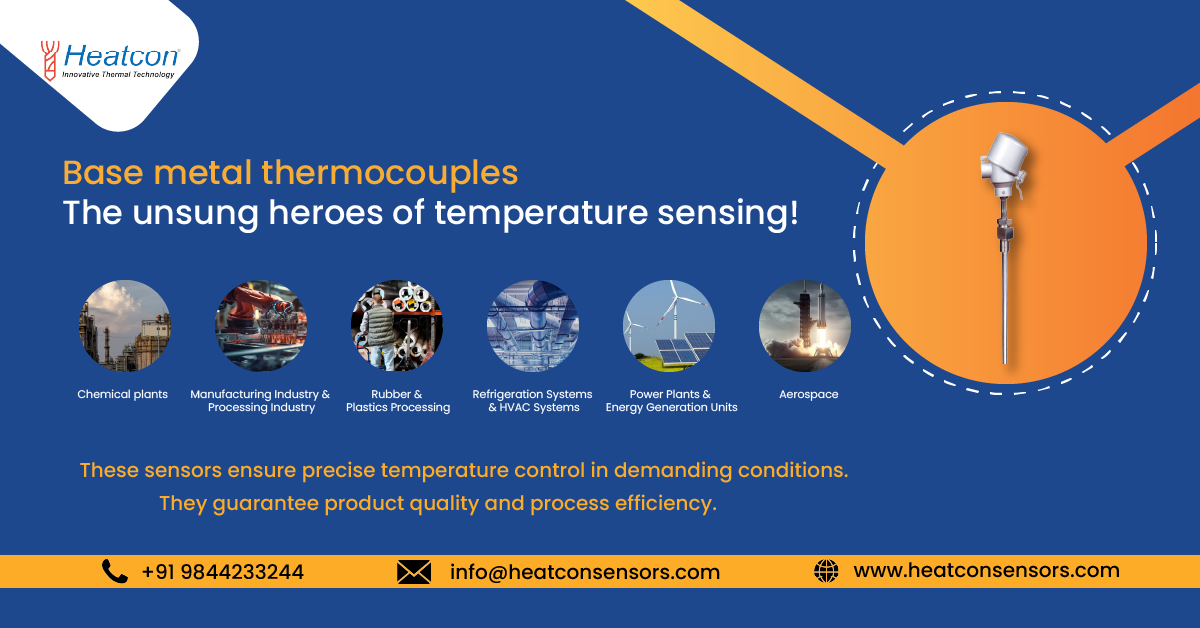

Industrial Applications of Base Metal Thermocouples

In the industry related processes where accuracy in temperature measurements is crucial, these base metal thermocouples contribute to maintaining product quality & enhancing production efficacy.

- Utilised in the food industry to monitor & control temperatures during cooling, cooking, and other storage processes to ensure safety & compliance with benchmarked quality standards.

- HVAC systems use these thermocouples to monitor air temperatures in ventilation, heating, & AC systems, promoting indoor comfort & energy efficiency.

Conclusively, these base metal thermocouples are essential devices for measuring temperatures in a broad range of industrial applications. Simplicity, durability, & affordability make these the preferred choices for engineers & technicians, who are looking for a highly reliable temperature measuring solution. By grasping the basics of these thermocouples and by understanding their applications, industry professionals can apply their skills to improve products’ quality, process control, and overall system efficacy in a variety of industries. Lay your hands on the most amazing products at Heatcon Sensors!