Thermocouples happen to be the indispensable devices useful in a wide array of industrial processes. These tools provide precise temperature readings even in harsh process environment(s). From the manufacturing sector to research labs, thermocouples tend to play a vital role in guaranteeing process safety & measurement efficiency. However, with surplus choices available around, selecting the apt one could be a herculean task.

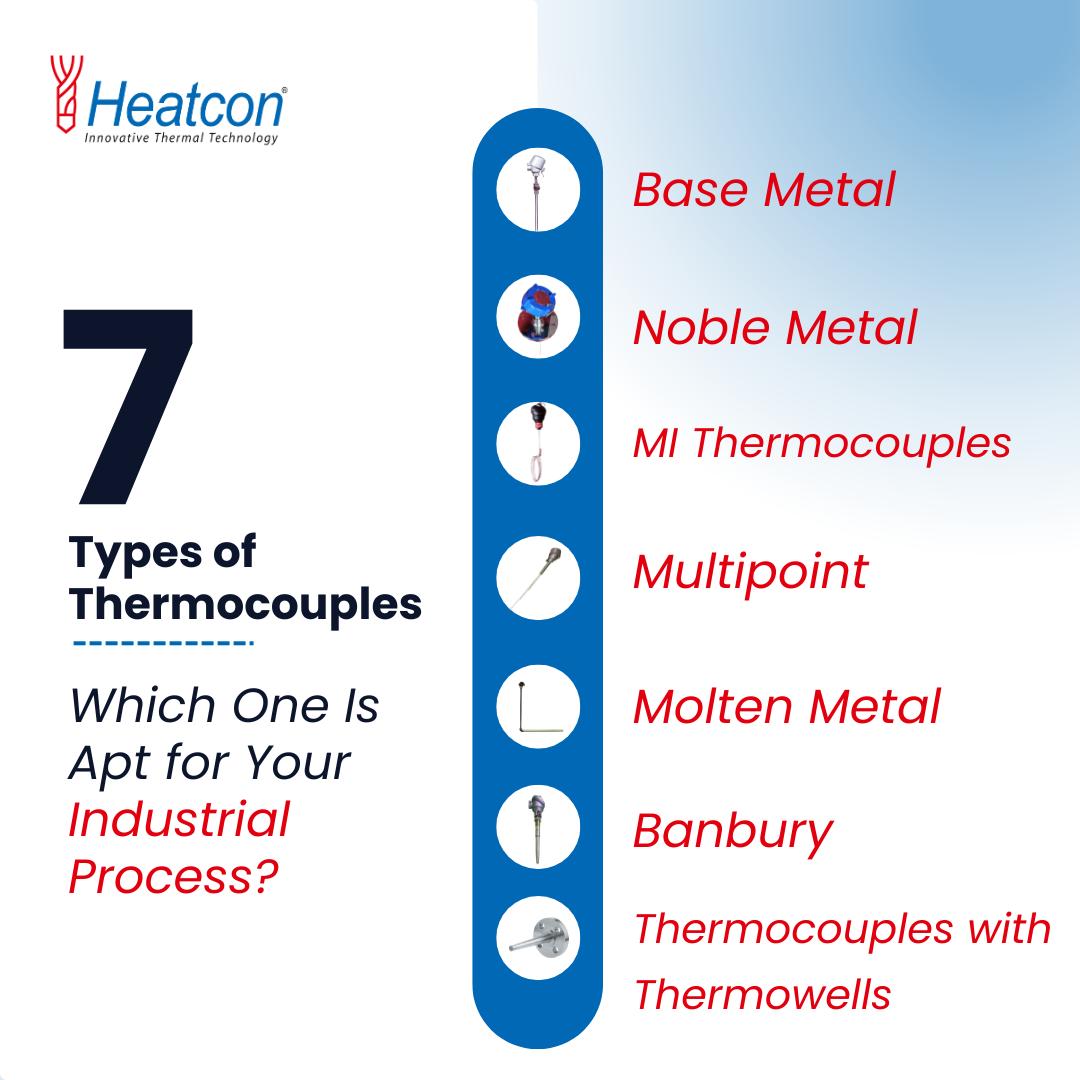

Types of Thermocouples

Let us study about the various types of thermocouples and their respective applications. This will help you make an informed decision about purchasing any one of them for your specific industrial application.

- Base Metal Thermocouples: These are cost-efficient & widely utilised in a number of industries. They are composed of reasonably priced metals like nickel, copper, and iron. They provide great sensitivity & good durability, which makes these thermocouples highly suited for all-purpose temperature sensing in varied environments with moderate ranges of temperatures.

- Noble Metal Thermocouples: They make use of precious metals like rhodium & platinum. They show great stability & high accuracy, especially in the applications with high-temperature ranges. These thermocouples are usually utilised in different industries including the aerospace segment, pharmaceuticals sector, and chemical processing industry where precise temperature control is vital.

- MI Thermocouples are composed of metal sheathed cables that are filled with powdered insulation of magnesium-oxide. Such a design gives flexibility & robustness. This makes these thermocouples ideal for harsh process environmental conditions, like high pressure conditions & corrosive atmospheres. These are usually utilised in the petrochemical sector, power generation segment, and metal refining industry.

- Multipoint Thermocouples: They have multiple sensing points along their length, enabling precise temperature profiling in different industrial applications. These thermocouples are widely utilised in several industrial applications like in heat treatments, semiconductor manufacturing, as well as environmental chambers wherein temperature homogeneity is vital.

- Molten Metal Thermocouples: These are specially constructed in such a way that they can withstand extreme temperature environments usually confronted in molten-metal processing applications. Manufactured from specialized materials such as ceramic & refractory metals, they guarantee precise monitoring of temperatures in foundries & metal casting industrial operations.

- Banbury Thermocouples: They are made for rubber & plastic processing equipment, especially in the Banbury mixers. These thermocouples are engineered in such a way that they can withstand high temperature situations & even abrasive materials, which are generally faced in rubber compounding industrial processes, guaranteeing reliable temperature control & measurements.

- Thermocouples with Thermowells: They provide protection from harsh process environments and also facilitate convenient installation & replacements (if the need be like). These act as barriers between the sensing elements & the processes, which extends the lifetime of these thermocouples and also enhances accuracy in measurements. These are used in industries like O & G, food processing, & petrochemicals.

From the different types of thermocouples, selecting the best one depends on a number of factors, including harsh process environments, temperature ranges, and distinctive application needs. Whether it is about sensing temperatures in a chemical reactor or guaranteeing product quality in some manufacturing procedure, investing in the right type of thermocouple is mandatory for accurate & reliable temperature readings & process optimization. You can rely on Heatcon Sensors to procure the best range of products.