What is a type K thermocouple and why is it so popular?

A type K thermocouple comprises a chromel (nickel-chromium) positive leg and an alumel (nickel-aluminum) negative leg. It is widely used because of its relatively high sensitivity (~41 µV/°C) and its useful temperature span from roughly –200 °C up to about +1250 °C (or higher under special conditions). In many industrial settings, the type K is the workhorse. When you design furnaces, ovens, hot zones, or any heat generating equipment (such as electric furnaces, cartridge heaters, hot air blowers), you’ll often rely on type K thermocouples for temperature feedback. Because Heatcon Sensors manufactures customized RTDs and thermocouples for industrial use across India and globally (in cities like Delhi, Mumbai, Bangalore, Dubai, Riyadh, Berlin, Seoul, Jakarta, etc.), our engineers are intimately familiar with how to interpret reference data and manage calibrations correctly.How do you read a type K thermocouple reference table?

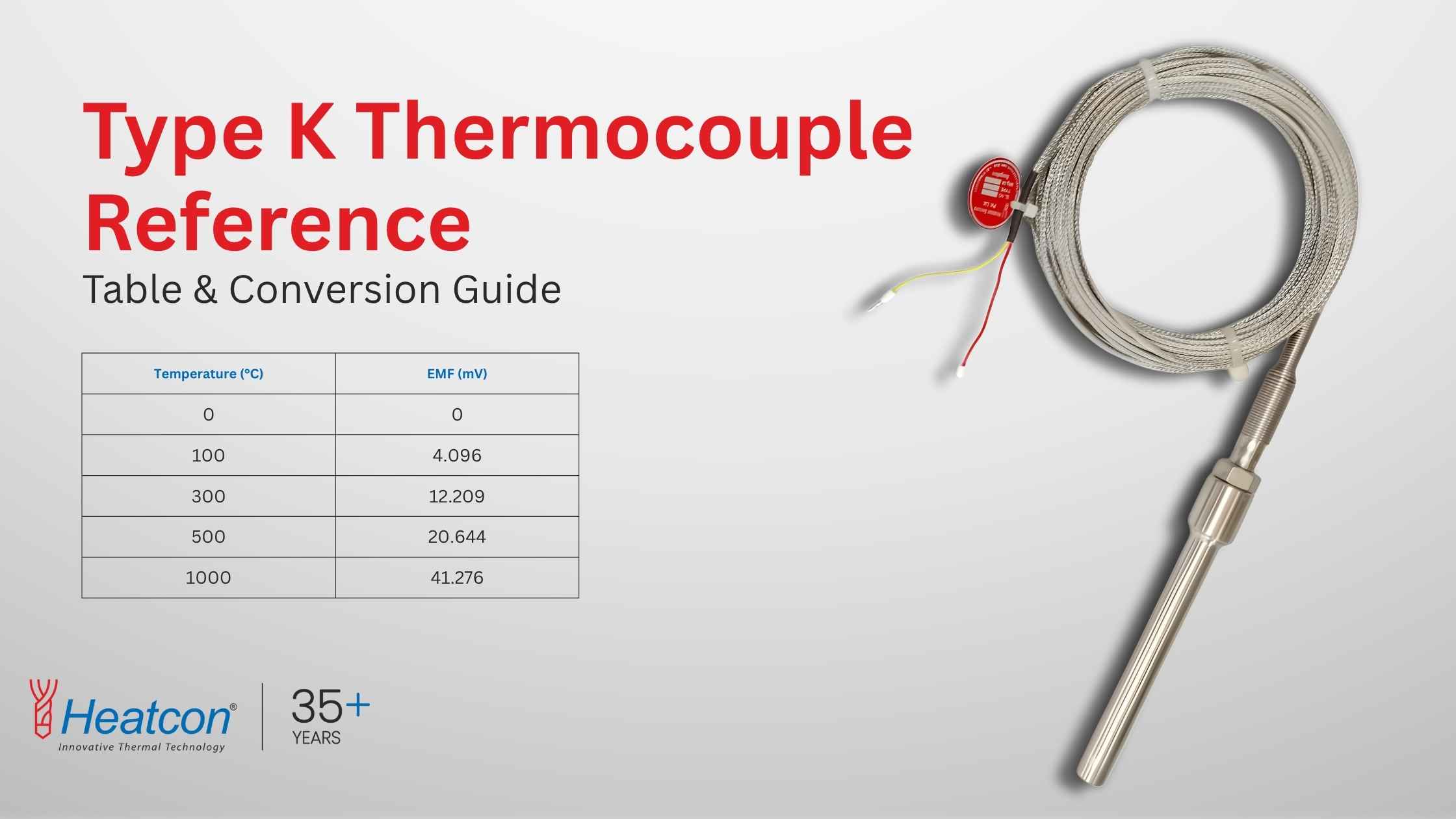

The table titled “type K thermocouple reference table” is a chart that correlates temperature (in °C or °F) to thermoelectric voltage (in millivolts). The reference junction is typically assumed to be at 0 °C (ice point). In practice, you can use such a table (or interpolation) to find the EMF for a given temperature or vice versa. Here’s a small excerpt from a reference table (Celsius) for illustration:| Temperature (°C) | EMF (mV) |

|---|---|

| 0 | 0.000 |

| 100 | 4.096 |

| 300 | 12.209 |

| 500 | 20.644 |

| 1000 | 41.276 |

How to perform thermocouple conversions (voltage ↔ temperature)?

The process of thermocouple conversions means converting between the measured millivolt signal and the corresponding temperature using the reference data. 1. Measure the output voltage (in mV) from the thermocouple circuit (with compensation for cold junction). 2. Use the “voltage reference table” (or a polynomial approximation) to map that voltage to temperature. 3. If necessary, do interpolation between table entries for greater precision. 4. Adjust for cold-junction compensation if your reference junction isn’t at 0 °C. For example, if your measured voltage is 4.096 mV, then thermocouple conversions using the table show it corresponds to ~100 °C. Many modern controllers and software embed polynomial formulas (for example from NIST ITS-90) so you don’t manually cross-reference tables each time.Using the EMF vs temperature graph

The EMF vs temperature graph is a visual plot of thermoelectric voltage against temperature. It helps you quickly see the linearity (or curvature) of the thermocouple response over its range. In practice, the graph is nearly linear over moderate ranges (say 0–400 °C), but deviates at the extremes. Using that graph, combined with the numerical table, can help you understand nonlinear segments and where errors may increase if interpolation is stretched too far.What is the thermocouple standard table and how does it tie in?

The thermocouple standard table (for type K) is the authoritative table defined in standards (such as NIST Monograph 175 / ITS-90) that specifies the voltage-temperature mapping with agreed tolerances. When you use the standard table, you can quantify measurement uncertainty, trace your calibration, and ensure conformity across systems.How to perform accurate calibration using the calibration guide?

A calibration guide for type K thermocouples typically includes a procedure such as: 1. Place the thermocouple junction in a known temperature bath or furnace (e.g. ice bath for 0 °C, fixed point furnaces like zinc, tin, etc.). 2. Ensure stable equilibrium and measure the output mV. 3. Compare against the thermocouple standard table (for that temperature). 4. Apply offsets or linear corrections, or record calibration coefficients. 5. For intermediate points, verify interpolation accuracy. 6. Document the results and maintain traceability (e.g., via national lab references). Using the calibration guide properly avoids drift, nonlinearity errors, and ensures your measurements are trustworthy — critical in furnace control, ovens, heat treatment, or thermal process industries.Why use a voltage reference table in your workflow?

A voltage reference table is your quick lookup that maps mV values to temperature (and vice versa). Embedded in software, instrument firmware, or printed in handbooks, it reduces computational overhead and manual guesswork. A typical voltage reference table covers many steps (say every 1 °C or 5 °C) so you can linearly interpolate between entries for precision.Common pitfalls and error sources

- Cold junction compensation errors: If your reference junction is not kept at a stable known temperature, the converted temperature will be offset.

- Nonlinear segments near extremes: At low (below –200 °C) or high (>1100 °C), table interpolation error grows.

- Thermocouple aging and drift: At high temperature, the wire alloys may change, altering the actual EMF response.

- Electrical noise, lead wire interference, or poor junction connections can alter measured voltage.

- Using a non-standard or mismatched table can introduce systematic bias. Always rely on the thermocouple standard table.

Example: Full conversion using table + interpolation

Suppose you measure 15.000 mV from a type K junction (cold junction at 0 °C). You want to find the corresponding temperature. You look up in the voltage reference table (or the standard table) and find 14.671 mV ≈ 380 °C, and 15.133 mV ≈ 370 °C (just for illustration). Interpolating linearly (approx), you estimate ~382–385 °C. You may cross-check on the EMF vs temperature graph to see if in that range linear interpolation holds well.How Heatcon Sensors leverages reference tables in custom sensor design

At Heatcon Sensors, we are temperature sensing specialists. We not only manufacture standard RTDs and thermocouples, but also customized RTDs and temperature sensors as per your industrial requirement. During design, our engineers refer to the type K thermocouple reference table, thermocouple standard table, and rely on thermocouple conversions and EMF vs temperature graph data to size amplification, filtering, cold junction compensation, and certification protocols. Whether you are in Bangalore, Pune, Kolkata, Delhi, Mumbai, or abroad in USA, UAE, Germany, South Korea, or Indonesia, we can supply custom sensors or full assemblies. For heat generating equipment — furnaces, ovens, hot air blowers, electric furnaces, high density cartridge heaters, infrared heaters, induction heaters — we integrate temperature sensors calibrated using our internal calibration guide, cross-checked against the voltage reference table, so you get measurement certainty across the full thermal range.How to choose between reference data sources and tables

Use trusted standards like NIST / ITS-90 published tables, prefer instrumentation or software that uses polynomial coefficients derived from those tables, and always document which reference table you used. At Heatcon Sensors, our calibration certification references the thermocouple standard table, and we include interpolation error margins in the delivered datasheet.Can Heatcon Sensors deliver this worldwide?

Yes. Heatcon Sensors ships temperature sensors and calibration-ready assemblies anywhere in India or the world — including cities like Bangalore, Chennai, Hyderabad, Mumbai, Delhi, and international hubs like New York, Dubai, Berlin, Seoul, Jakarta, Riyadh, Moscow, etc. So even if you are in remote locations or high-tech zones globally, you can rely on us for custom thermocouples with traceability to the same reference tables and calibration guide we use in-house.Why you should not leave your project without this reference insight

Without the right type K thermocouple reference table, without properly doing thermocouple conversions or calibration, you risk measurement errors, process inefficiencies, safety margins out of tolerance, and perhaps noncompliance. By partnering with Heatcon Sensors, you get more than the hardware — you get confidence, traceability, support, and a data-driven approach grounded on known tables and graphs. Don’t leave your thermal design to guesswork when you can have calibrated, custom sensors from a manufacturer who understands reference tables inside out.How to reach Heatcon Sensors now

To get started with a custom temperature sensor or thermocouple solution backed by exacting reference data and calibration, you can:- Submit your information on the form at heatconsensors.com/contact-us/

- Leave a WhatsApp message via the interface available on Heatcon Sensors’ website

- Call us on +91 9164833027 or +91 9844233244 for immediate assistance

About Heatcon Sensors

Heatcon Sensors is a premier Indian manufacturer of precision temperature measurement devices. We specialize in custom RTDs, thermocouples, sensor assemblies, and fully integrated measurement systems. Over the years, we have built domain expertise in industrial furnaces, ovens, hot air systems, electric furnaces, cartridge heaters, infrared heaters, and related heat-generating systems. Our commitment to traceability, calibration integrity, and application engineering ensures that every sensor delivered conforms to your expected standard and works reliably in your process.Type K thermocouple reference table & conversion guide — Frequently asked questions

The table maps measured millivolts to temperature with a 0 °C reference junction, letting engineers convert signals into reliable process values without guesswork. Use it during design, commissioning, and troubleshooting to validate readings and to document setpoints or alarms against a common, standards-aligned baseline that your whole team can share.

- Quick lookup for commissioning and audits.

- Baseline for controller scaling and limits.

- Shared reference across plants and vendors.

Heatcon Sensors supplies sensors pre-documented with the same reference so your instrumentation, PLC/SCADA tags, and reports stay consistent.

The plot shows thermoelectric voltage (mV) against temperature, highlighting near-linear response in mid-ranges and curvature at extremes. It quickly flags where interpolation is safe and where polynomial corrections are advisable. Use it to sanity-check odd readings, choose controller input ranges, and anticipate error growth at very low or very high temperatures.

Our engineers at Heatcon Sensors use this visual alongside tables during sensor selection for furnaces, ovens, and hot air systems to keep your control loops stable.

They are the steps to translate a Type K millivolt reading into temperature (or the reverse). Measure the mV signal, apply cold-junction compensation, then map to temperature using trusted data or polynomials. For precision, interpolate between table entries and verify against a known point. Document which coefficients or tables you used so results remain traceable.

- Measure mV and record ambient reference.

- Apply compensation (hardware or software).

- Look up or compute the corresponding temperature.

- Validate with a stable check point (e.g., ice bath).

Heatcon Sensors can ship sensors with calibration sheets so your conversions align with your quality system.

Use a printed or digital lookup whenever you commission new inputs, diagnose suspicious values, or verify third-party instruments. Auto-scaling is convenient, but independent checks with a voltage reference table expose wiring polarity mistakes, cold-junction errors, or firmware misconfiguration before they affect production.

Heatcon Sensors provides reference-aligned documentation with custom probes for regulated environments where independent verification is required.

Intervals depend on temperature duty and criticality: heavy high-temp service may need quarterly checks; moderate duty often suits semi-annual or annual cycles. A robust procedure defines reference points, stabilization times, acceptable tolerances, traceability, and documentation, plus drift criteria for repair or replacement.

- Use stable baths/furnaces and certified indicators.

- Log reference, reading, offset, and uncertainty.

- Tag sensors with calibration status and due date.

Ask Heatcon Sensors for calibration support and application-matched intervals for your plant conditions.

If your PLC, indicators, and lab software reference different standards or coefficient sets, the same mV produces inconsistent temperatures. Aligning everything to one recognized dataset prevents hidden biases, eases audits, and simplifies troubleshooting across shifts and suppliers.

Heatcon Sensors aligns shipped data sheets and calibration notes to the same standard so your ecosystem stays consistent.

We design probes for the thermal and mechanical realities of your line—choosing sheath alloys, insulation, junction type, and lead construction that survive duty cycles. Each assembly is documented against a consistent reference, with optional calibration, traceability, and accessories like mineral-insulated cables for noise immunity and longevity.

We also manufacture complementary heat-generating equipment (e.g., furnaces, ovens, hot air blowers, electric furnaces, high-density cartridge heaters) and integrate the sensing strategy upfront so control loops stay tight from day one.

Yes. We custom-manufacture RTDs and thermocouples in India and ship worldwide with region-appropriate documentation, measurement units, and certificates. Whether your facilities are in the Middle East, Europe, the Americas, or Asia-Pacific, we align testing and paperwork to your compliance framework and commissioning timelines.

To begin, send your specification through our contact form, use the site’s WhatsApp interface, or call +91 9164833027 / +91 9844233244 for immediate assistance.