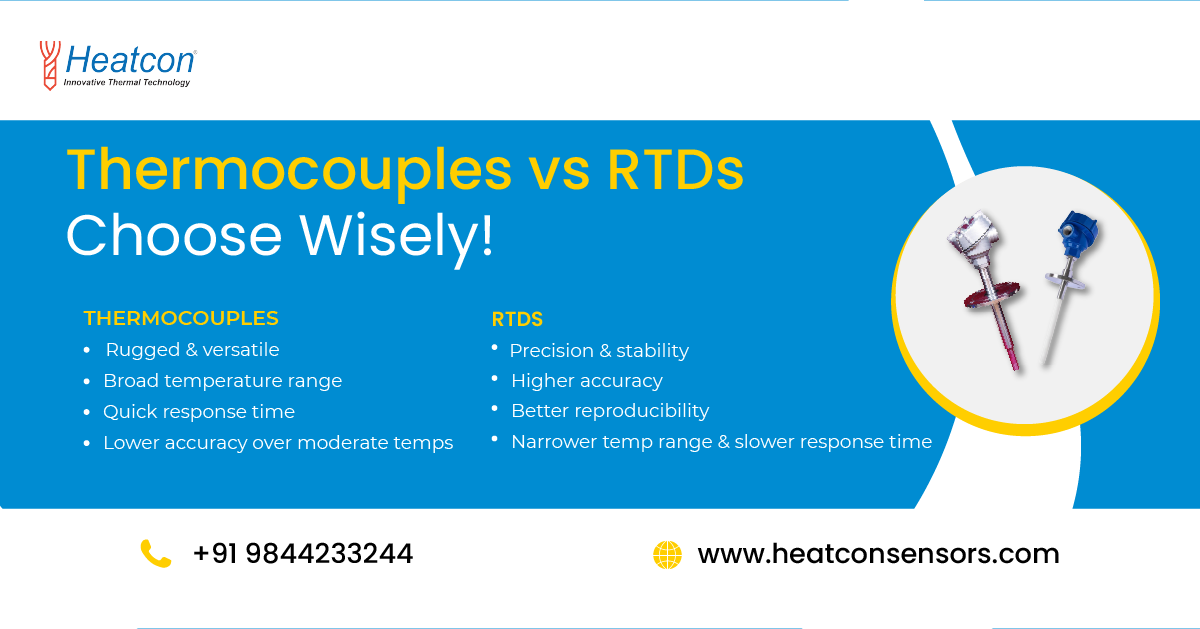

Talking about the domain of temperature measurements, thermocouples, and RTDs, including the full form of RTD sensor (resistance temperature detector), are the two leading choices. Both of these have their strengths & weaknesses and are tailored to varied application requirements. To choose the best option for your specific scenario, it is important to fathom their relative worth by analysing the merits each of them provides.

Thermocouples

The thermocouple is characterized by its rugged & versatile nature. Thermocouples consist of two different metal wires that generate a voltage proportional to the temperature range of RTD and thermocouple junctions. This mechanism enables thermocouples and RTDs to handle a broad temperature range, catering to diverse environments. One of the main benefits of these sensors is their quick response time, making them apt for dynamic temperature sensing applications. Also, thermocouples are relatively cheaper and could be manufactured in different configurations to best suit various process environments. However, these sensors have some limitations too. Their accuracy could be impacted by factors like oxidation, material purity, and device aging. So, these usually have lower accuracy in comparison to RTDs, specifically over a moderate range of temperatures.

Resistance Temperature Detectors (RTDs)

An RTD happens to be a precision temperature sensor whose resistance augments linearly with temperature. Usually made of platinum, these sensors provide greater accuracy and higher stability than thermocouple RTD combinations, especially in medium temperature ranges. A main advantage of using an RTD is its higher accuracy & better reproducibility. RTDs provide reliable & consistent temperature readings that are less likely to drift over time. In addition, an RTD has excellent linearity & better stability, which makes it suited for those industrial applications where precise temperature control is quite significant. RTDs also have some limitations, like their higher cost compared to thermocouples, a narrower RTD temperature range (usually -200°C to 850°C), and slower response times than thermocouples. So, RTDs might not be ideal for those industrial applications that require quick temperature changes.

Best Use Cases

The choice between a thermocouple or an RTD largely depends on the specific needs of the industrial application. Thermocouples and RTDs are suitable for high-temperature applications where robustness and versatility are critical, such as aerospace applications, exhaust gas monitoring, and industrial ovens. RTDs are better suited for industrial applications requiring high accuracy and stability over a specific RTD range temperature, such as lab environments, food processing, and pharmaceuticals.

In summary, both thermocouples & RTDs have significant benefits & pitfalls. Choosing the right sensor is largely dependent on factors like temperature ranges, precision needs, response times, and budget constraints. To make informed decisions in temperature sensing applications, it is crucial to fathom the strengths, weaknesses, and best use cases for each type. Shop for the best range of products from Heatcon Sensors.