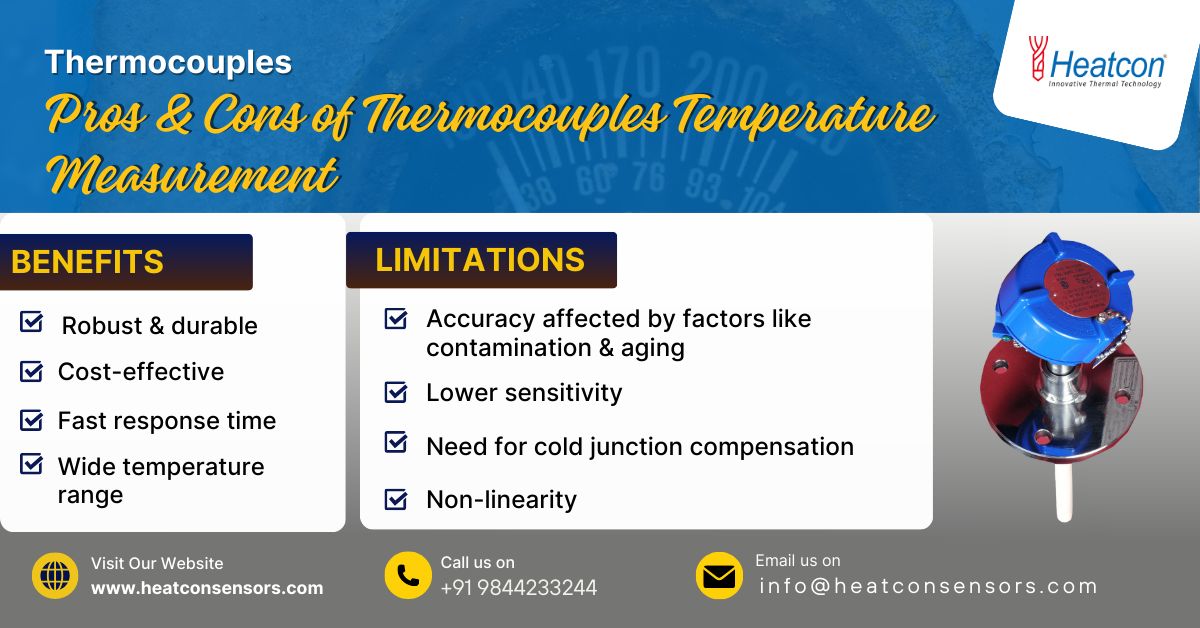

The process of temperature measurement is essential for many industrial processes, from the manufacturing processes to scientific research and many more. Amongst the various devices that are available around for sensing temperatures, the most widely used ones are thermocouples in temperature measurements. These tools have their own set of benefits as well as some limitations and are prone to continued evaluation & development in temperature sensing applications.

Benefits

- Robust Nature: Thermocouples are manufactured without sensitive components such as semiconductors and/or filaments, making them robust against mechanical shock(s) & vibration(s). Their durability makes them ideal for harsh process environments like those seen in industrial machinery & automobile engines.

- Cost-Efficiency: Thermocouples tend to provide cost-efficient solutions for temperature measurements, specifically in large installations where more than one sensor is required. The simplicity of design and efficiency of manufacturing makes them reasonably priced.

- Rapid Response Time: In comparison to other similar temperature sensing equipment, thermocouples tend to have faster response times and they provide real-time data as well, which is important for processes that need rapid adjustments. Such a property of these sensors is especially useful in applications like HVAC systems & food processing etc.

- Broad Temperature Range: Thermocouples tend to be ideal for extreme temperature environments from cryogenic to even very high temperature conditions. Such versatility makes these sensors highly essential tools in industries where large temperature differences are seen like in metallurgy processes, aerospace industry, as well as automotive sector.

Limitations

- Non-Linearity: The nonlinear relationship between device’s temperature & its voltage output makes interpretation of measurements difficult, specifically over wide temperature ranges. Solving this problem often needs linearization techniques or some special equipment at times.

- Affected Accuracy: Thermocouples cover a broad temperature range, but in turn their precision could be affected by some factors like material contamination, aging of the device, & calibration drift. Such limitations need periodic recalibrations & certain correction techniques for maintaining accuracy.

- Lower Sensitivity: These sensors have limited sensitivity in comparison to other similar sensors like RTDs & thermistors etc. This reduced sensitivity could possibly result in diminished resolution & decreased accuracy, especially in applications that require good temperature control.

- Cold Junction Compensation: These sensors need temperature compensation at the junction where the wire connects to the measuring meter. Failure to properly compensate for this cold junction can lead to errors, specifically in those process conditions that have fluctuating ambient temperatures.

In summary, thermocouples have a mix of benefits & limitations in temperature sensing applications. Their broad temperature range, rapid response times, and robust nature make them essential in many industries. However, certain limitations like accuracy issues, non-linearity, and cold junction compensation needs highlight the significance of meticulous consideration & use of proper implementation techniques while using them. As technology is advancing with each passing day, ongoing R&D efforts that are ongoing are aimed at alleviating these drawbacks and guaranteeing that these sensors remain important tools in temperature sensing applications. You can get excellent products from Heatcon Sensors where you won’t have to worry about the quality!