Need of Temperature Measurement in Varied Industrial Settings

Temperature measurements happen to be quite crucial for a variety of industry-related processes in varied industrial settings having different process environments. Right from the manufacturing industry to food production and many more, temperature sensing is a vital element in all of these. Among the multitude of temperature measuring tools available around, thermocouples with thermowell surpass owing to their dependable & versatile nature.

Role of Thermocouples in Temperature Measurements

At the core of different temperature measuring systems are the thermocouples, which happen to be the sensors that produce a voltage proportional to the temperature differences between the junctions. This basic principle tends to make thermocouples suitable for a broad range of industry-related applications in varied process environments from cryogenic ranges to even high-temperature conditions.

Thermocouples with Thermowell

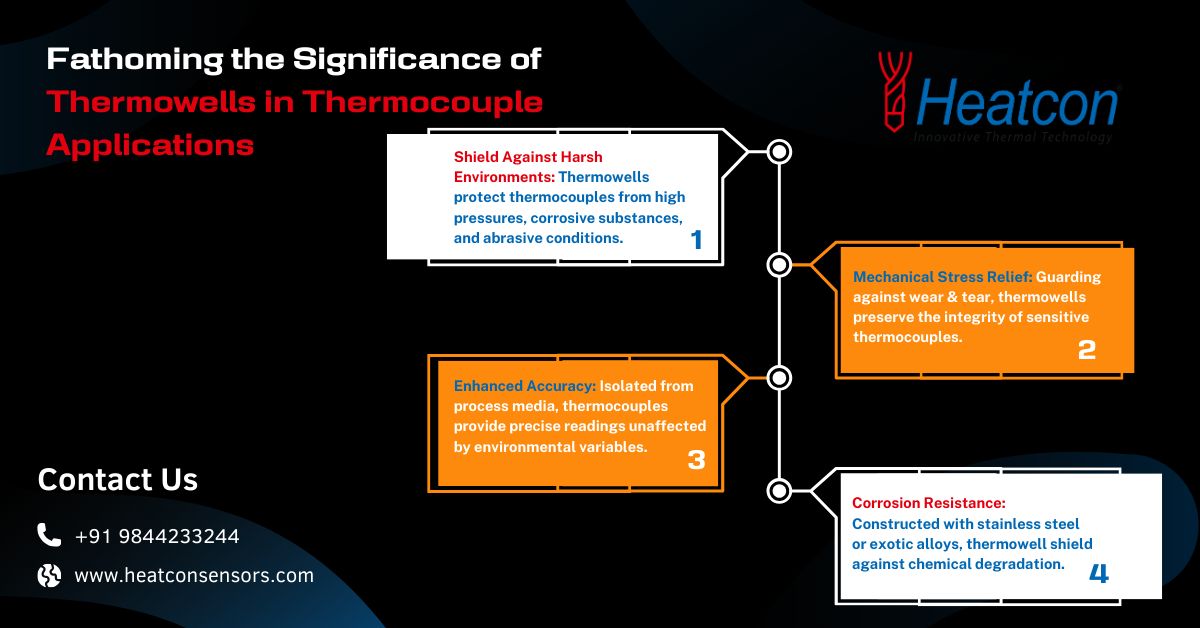

Thermocouples’ effectiveness could be increased by installing protective tubes in measurement setups. Thermowells are those protective encases that house temperature sensors to protect them from challenging process environments like high pressures, flow-induced vibrations, and corrosive atmospheres. These also facilitate comfortable sensor installations, easy maintenance, and quick replacements without any interruptions to the processes.

Advantages of Using Thermocouples with Thermowell

- Increased Lifespan: Using thermocouples with thermowell extends the shelf life of the sensor and also augments sensor accuracy. The thermowell isolates the sensor from the process medium, thus preventing direct contact and in turn decreasing the risk of any chemical corrosion & mechanical damage. Such shielding guarantees dependable & consistent temperature measurements over longer periods, which contributes to the overall efficacy & safety in various industry-related operations.

- Flexibility: A thermowell allows flexibility in sensor selection & sensor installation. Different types of thermocouples (Type K, Type T, or Type J) could be utilized as per the specific temperature ranges as well as different process environments of industrial applications. Also, thermowells are available in a variety of materials, like stainless steel, ceramic, Inconel, etc., which allows better compatibility with a broad range of process fluids as well as process conditions.

- Clean Usage: In those industrial applications where hygiene & sanitation are critical for the process functioning, like in the pharmaceutical industry & F&B, thermowell tends to play a critical role in guaranteeing product quality and ensuring regulatory compliance. Their smooth surface & gap-free construction prevent any bacterial growth, which helps in the hygienic use of thermocouples that are also easy to clean & sterilize.

- Safety: A thermowell increases safety by creating a physical barrier between the sensor & the process. In harsh challenging environments with extreme temperatures or exposure to toxic substances hold a major concern, thermowells reduce the risk of sensor failure or any leakages, which protects people as well as equipment from any potential harm.

In summary, the combination of thermocouples with thermowell provides robust solutions for precise & dependable temperature readings in a variety of industry-related applications. By giving flexibility, protection, & safety, a thermowell tends to extend the performances & longevity of thermocouple-based industrial temperature measuring systems, guaranteeing optimum process control as well as productivity. You are sure to lay your hands on the most amazing products at Heatcon Sensors.