Heater banks, also known as electric heater banks or resistance heater banks, are assemblies of multiple electric heaters arranged in a specific configuration to provide efficient and controlled heating. They are widely used in various industrial and commercial applications, including process heating, space heating, and drying.

Types of Heater Banks

Heater banks can be classified based on their construction and heating elements:

- Finned tube heater banks: These banks consist of a series of finned tubes, each containing a heating element. The fins increase the surface area, enhancing heat transfer efficiency.

- Cartridge heater banks: Cartridge heaters are inserted into holes drilled into a metal plate or frame, forming the heater bank. They offer flexibility in terms of arrangement and power output.

- Strip heater banks: Strip heaters are flat, rectangular elements that can be arranged in various configurations to create heater banks. They are often used in applications requiring uniform heat distribution.

- Immersion heater banks: These banks are designed to be immersed in liquids or gases for heating purposes. They are commonly used in tanks, vats, and boilers.

Applications of Heater Banks

Heater banks have a wide range of applications, including:

- Process heating: Heating liquids, gases, or solids for various industrial processes.

- Space heating: Heating large spaces such as warehouses, factories, and commercial buildings.

- Drying: Drying materials such as wood, textiles, and food products.

- Mold heating: Heating molds for plastic injection molding and other processes.

- Temperature control: Maintaining a specific temperature in various applications.

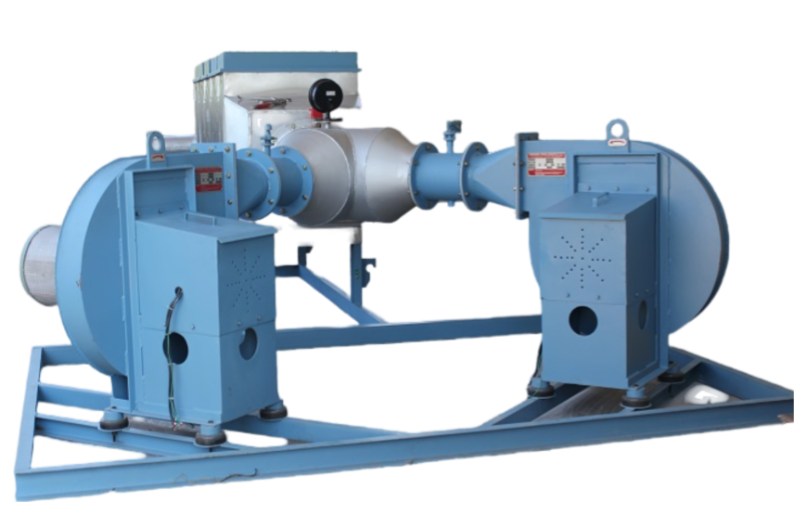

Key Components of a Heater Bank

A typical heater bank consists of the following components:

- Heating elements: These are the primary components that generate heat. They can be made of various materials, such as nichrome, stainless steel, or ceramic.

- Enclosure: The enclosure houses the heating elements and provides protection and insulation.

- Controls: Controls are used to regulate the temperature and power output of the heater bank.

- Termination box: This box contains the electrical connections for the heater bank.

Factors to Consider When Choosing a Heater Bank

When selecting a heater bank, consider the following factors:

- Power rating: Choose a heater bank with sufficient power output to meet your heating requirements.

- Temperature range: Ensure the heater bank can operate within the desired temperature range.

- Voltage and current: Select a heater bank compatible with your electrical supply.

- Enclosure material: Consider the enclosure material based on the operating environment and temperature requirements.

- Installation and maintenance: Evaluate the ease of installation and maintenance of the heater bank.

By carefully considering these factors, you can select the most appropriate heater bank for your specific application.

Heatcon Sensors: Your Customized Heater Bank Solution

Heatcon Sensors stands out as a leading heater bank manufacturer renowned for its ability to deliver tailored solutions that meet the precise needs of its customers. With a commitment to innovation and excellence, Heatcon Sensors offers a wide range of customizable heater banks designed to cater to diverse industrial applications.

Customization Options at Heatcon Sensors

- Heating Element Configuration: Select the most suitable heating element type (finned tube, cartridge, strip, or immersion) based on your application and performance requirements.

- Power Output: Tailor the power output to match your specific heating needs, ensuring efficient and effective operation.

- Enclosure Material: Choose the appropriate enclosure material, such as stainless steel or aluminum, to withstand harsh environments and provide durability.

- Dimensions and Size: Customize the size and dimensions of the heater bank to fit your equipment and workspace constraints.

- Control Systems: Integrate advanced control systems for precise temperature regulation and monitoring.

- Safety Features: Incorporate additional safety features, such as overtemperature protection and emergency shutdown, to enhance workplace safety.

Benefits of Customized Heater Banks from Heatcon Sensors

- Enhanced Efficiency: Tailored solutions ensure that the heater bank operates at peak efficiency, maximizing productivity and minimizing energy consumption.

- Improved Process Control: Customized features provide greater control over your heating processes, leading to improved product quality and consistency.

- Increased Versatility: Customizable heater banks can be adapted to a wider range of applications, expanding their utility within your operations.

- Cost-Effectiveness: By investing in a customized heater bank, you can avoid the need for multiple standard units, potentially saving on costs.

Experience the Heatcon Sensors Difference

When you choose Heatcon Sensors for your heater bank needs, you’re partnering with a company dedicated to providing innovative, reliable, and customized solutions. Our team of experts will work closely with you to understand your specific requirements and deliver a tailored product that exceeds your expectations.

Contact Heatcon Sensors today to discuss your heater bank needs and explore the possibilities of customization.