In the field of industrial processes where precision heating is quite essential in certain applications, cartridge heaters stand as powerful & indispensable components. These rather small, yet highly powerful devices contribute to a gamut of industries, from aerospace industry to even medical equipment manufacturing and whatnot! As technology is advancing with each passing day, these devices are also innovating, ushering in a completely new era of efficacy, reliability, efficiency, and versatility.

Energy Efficiency

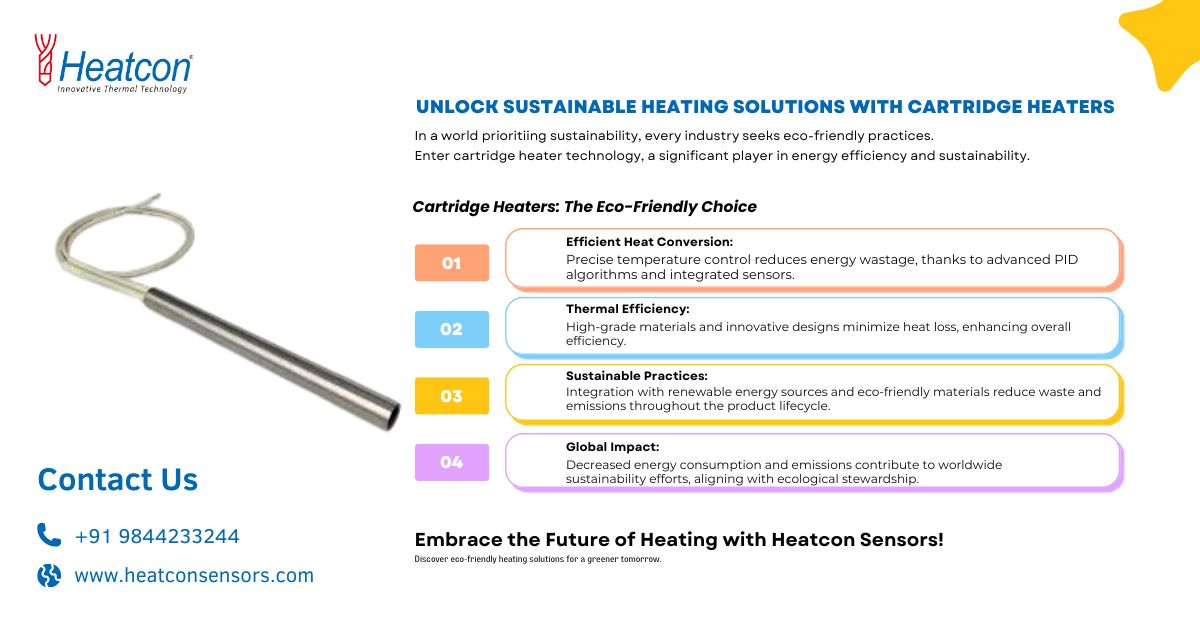

A notable trend in cartridge heater technology happens to be the prominence of energy efficiency. As sustainability is fast becoming more & more significant, such heaters are now being manufactured, which tend to consume lesser power while still keeping up with their optimal heating performance. Such a task is achieved through advancements in insulation materials, and with the help of integrating smarter heating controls, which tend to better regulate temperatures.

Compact Designs

The miniaturization approach has been followed in the electrical industry big time! This has made it possible for smaller, more compact designs of these heaters without compromising on their heating capacities. Such a trend is especially beneficial in those industrial applications where there is limited space, like in the automotive sector & the electronics domain, etc. These compact cartridge heaters provide larger flexibility in designs & installation, thus paving the way for fresh opportunities for engineers & designers alike.

Wireless Connectivity & IoT Capabilities

One more significant innovation in cartridge heater technology is the integration of wireless connectivity & IoT (Internet of Things). It is now very much possible to remotely monitor & control the temperatures during industrial processes from any place. This tends to increase efficiency and also helps in predictive maintenance, thus decreasing downtime as well as maintenance costs.

Sturdy Nature

Innovations in material science have resulted in the development of such heaters that can withstand harsh environments & extreme temperatures. This is essential for those industrial applications where equipment operates in difficult circumstances like in O & G etc. Manufacturers are using high-temperature alloys & advanced ceramic materials. This is to ensure the durability and longevity of these heaters in challenging situations.

PID (Proportional-Integral-Derivative) Controllers

In the medical field, precision & reliability are quite significant. This has led to a growing demand for heaters with fast response times and precise temperature control. Manufacturers are increasingly producing cartridge heaters with advanced PID controllers and feedback mechanisms to meet the needs of highly sensitive applications.

The Promising Future of Cartridge Heater Technology

The future of cartridge heater technology is very promising. Ongoing R&D efforts on materials, designs, and control systems promise further improvements in reliability, efficiency, and performance. From better thermal conductivity material to new heating element designs, the prospects are truly limitless.

Ending Note

Conclusively, advancements in cartridge heater technology have revolutionized the heat management domain in a plethora of industries. Energy-efficient heater designs, wireless connectivity integration, and advanced materials are improving efficiency, reliability, and versatility in industrial heating. You are sure to make the best purchases from Heatcon Sensors!