Talking about temperature measurements in industrial processes, thermocouples happen to be the requisite devices. These sensors rely on the thermoelectricity principle. They are omnipresent across a myriad of industries where precise temperature sensing is all-important. However, what’s behind the scenes? Well! They are “thermowells;” the unsung heroes that ensure the reliability & longevity of these thermocouples!

Significance of Thermowells in Thermocouple Applications

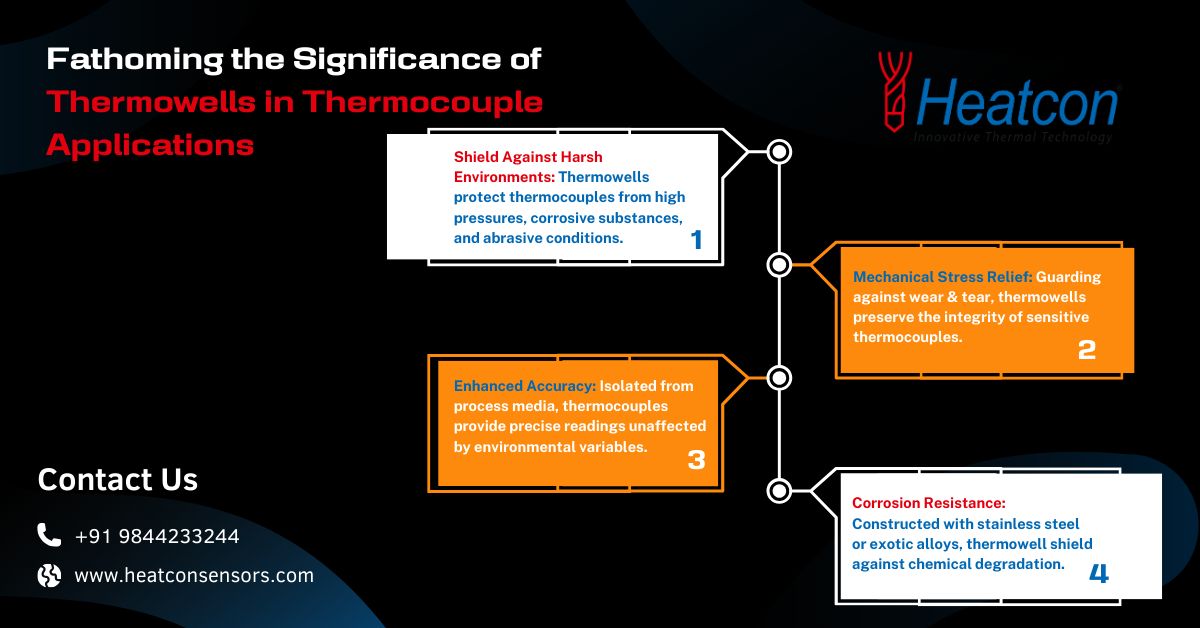

Thermowells happen to be those protective enclosures that are designed in such a way that they help shield thermocouples from the harshness of challenging process environments. These are usually constructed from metals or ceramic materials. Thermowells give thermocouples much-needed buffers against high pressures, corrosive substances, as well as abrasive conditions, which can otherwise lead to compromises in the sensor’s accuracy & shelf life.

- Thermowells Enhance the Accuracy of Thermocouples: A chief function of a thermowell is to help in making precise temperature measurements. Thermowells isolate thermocouples from the process media, which helps guarantee accurate temperature readings that are not affected by the surrounding variables of the process environments. For example, in an industrial setting that has fluctuating pressures and/or aggressive chemicals, direct exposure of thermocouples to the process media can result in inaccuracies or even sensor damage. In such scenarios, thermowell helps by mitigating such risks and thus guaranteeing consistent & reliable temperature sensing data.

- Thermowells Protect Thermocouples Against Mechanical Stresses: Thermocouples are thus ultra-sensitive devices that are prone to mechanical stress and vibration-induced wear & tear. For such instruments, Thermowells tend to work as guards that absorb any external forces and preserve the integrity of these sensors. The need for these shields is usually quite significant in industries like O & G, where the equipment tends to operate under extreme process conditions, which may include turbulent flows & high velocities etc.

- Thermowells Make Thermocouples Corrosion Resistant: In harsh process conditions, if thermocouples are not protected properly then it can lead to deterioration, thus risking temperature measurement accuracy & process safety. Thermowells tend to be constructed using corrosion-resistant material like stainless steel or an exotic alloy. This provides the much-needed barriers against any chemical degradations. Such features of thermowells help in industries including the chemical processing industry etc, where exposure of thermocouples to corrosive substances is quite common.

- Thermowells Facilitate Maintenance & Calibration of Thermocouples: Thermowells help streamline maintenance & calibration procedures of thermocouples. When the sensors are encapsulated within these removable houses, the technicians can very easily access & service the thermocouples without the need to disrupt the entire process or without requiring any specialized equipment. Such accessibility reduces downtime and also ensures quick resolution of any such issues, thus aiding in better operational efficiency.

In the complex area of temperature measurements, thermowells tend to be indispensable in safeguarding the accuracy, reliability, & longevity of thermocouples. From harsh industrial surroundings to corrosive lab settings, these enclosures guard thermocouples against harsh external variables, which could otherwise compromise the performance of the sensors. By understanding the significance of thermowells in thermocouple applications, industry leaders can optimize their processes, thus enhancing safety, & upholding stringent quality standards. As technology is evolving every minute, this synergy between thermocouples & thermowells would remain central in guaranteeing accurate temperature sensing across a range of industrial applications. Get the best products from Heatcon Sensors!